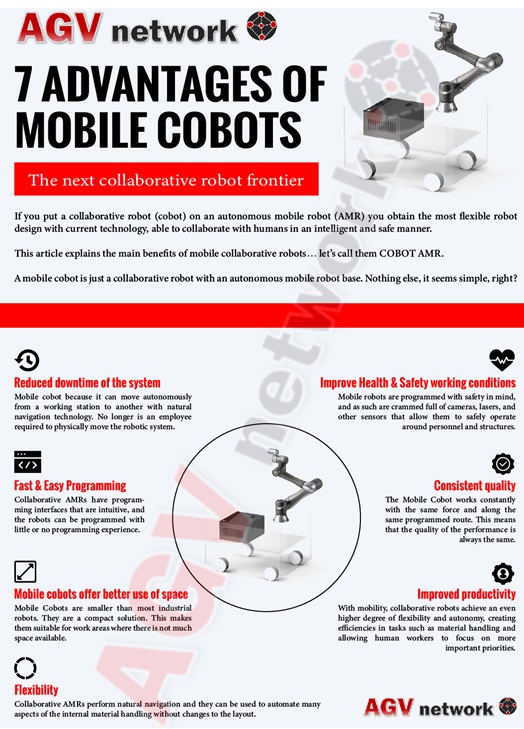

✅ 7 Advantages of Mobile Cobots. The next collaborative robot frontier.

If you put a collaborative robot (cobot) on an autonomous mobile robot (AMR) you obtain the most flexible robot design with current technology, able to collaborate with humans in an intelligent and safe manner.

This article explains the main benefits of mobile collaborative robots… let’s call them COBOT AMR.

Mobile Collaborative Robots open limitless low cost automation opportunities

What is a mobile cobot?

A mobile cobot is just a collaborative robot with an autonomous mobile robot base. Nothing else, it seems simple, right?

Mobile Cobots industry is growing and represents one of the main examples of autonomous mobile robots applications.

Why should you deploy mobile cobots? What are the main pros of autonomous mobile cobots?

When you combine two advanced technologies, the general stance is to use the best of both worlds. So, here we take the best of the COBOT and the best of the AMR and you have your benefits.

These benefits go beyond the typical advantages of AGVs.

Cobots collaborate with humans reducing operator interventions and boosting their productivity benefits.

With the addition of mobility, collaborative robots can achieve a huge degree of autonomy, creating efficiencies in tasks such as material handling and allowing human workers to focus on more important priorities.

The increased efficiency benefits of mobile collaborative robots cannot be ignored; they are flexible, scalable and easy to integrate and customize.

What are the benefits of Mobile Cobots?

1. Reduced downtime of the system

3. Mobile cobots offer better use of space

4. Improve Health & Safety working conditions

1. Reduced downtime of the system

The main advantage of including mobility in collaborative robots is the reduced downtime of the system.

In the past, the setup of stationary robot systems or changing their set locations required a long process that needed skilled personnel every time something was altered.

A stationary robot can sit idle for some time until someone is ready to move it. It must be manually moved between tasks, or an elaborate system to move the part to the robot must be implemented.

This is time consuming and expensive for dynamic companies that often change processes and layouts.

These problems are solved with a mobile cobot because it can move autonomously from a working station to another with natural navigation technology. No longer is an employee required to physically move the robotic system.

The additional mobility simplifies the process while increasing uptime. Moreover, the members of your team don't waste time changing over the robot between tasks. They can focus on more value-added tasks.

2. Fast and Easy Programming

When you deploy mobile robots, there are two different things to program:

- The COBOT

- The Mobile Robot Base

Luckily, both are designed to be programmed easy and fast.

Traditional robots require a lot of knowledge and time to program actions and can often perform just one action. Any change to the required actions would also need additional programming.

Thanks to user-friendly software, cobots are much easier to program. They can learn new actions and can be quickly implemented in a process, which may include performing different tasks upon different triggers.

Same as the COBOT, the main features of an AMR compared to an AGV are its flexibility and facility of deployment.

Installing an AMR doesn’t require complicated algorithms or calculations. All you need to do is to just drive your AMR manually; its natural navigation maps the environment; then just tell it where to go…. and it’s done. The AMR can map and navigate just checking the surrounding area.

Collaborative AMRs have programming interfaces that are intuitive, and the robots can be programmed with little or no programming experience.

Considering that you can have a cutting-edge autonomous and collaborative solution in just a couple of hours, mobile cobots could be seen as temporary employees or flexible employees who can perform different tasks in different departments.

3. Mobile cobots offer better use of space

Let’s take a look at this advantage… mobile robots move, so they do not occupy defined areas for long periods of time.

Mobile Cobots are smaller than most industrial robots. They are a compact solution. This makes them suitable for work areas where there is not much space available.

Cobots use less space than traditional industrial robots because they don't need safety fencing. Mobile cobots, can be stored in one location and move to other locations as needed.

4. Improve Health & Safety working conditions

Mobile Cobots have built-in safety features that enable them to work alongside humans. This means that the Cobot not only has an emergency stop button, but they can also be programmed to stop when a human enters the area where the robot operates.

Mobile robots are programmed with safety in mind, and as such are crammed full of cameras, lasers, and other sensors that allow them to safely operate around personnel and structures.

Workers who must carry out a lot of repetitive work can suffer from various complaints and long-term lesions. The physical strain for the worker increases with the weight that has to be handled. This is increasingly a problem with hourly task requirements as a function of job performance.

Give dirty, dangerous, and tedious jobs to cobots to reduce repetitive strain and accidental injuries. This means that worker’s comp decreases with fewer workplace injuries.

A Cobot can repetitively handle heavy products, and relieve workers from physical strain and reduce absenteeism from work.

Collaborative AMRs are tools to support employees in their work, relieving them of many heavy, unergonomic and time-consuming tasks and reduce the overall risk of collisions.

AMR Cobots are designed to work with people and not to replace them. The target is making workers job easier avoiding dirty, unsafe, boring, monotonous, or repetitive tasks.

On the other side, employees will have more time to perform tasks needing creativity, solution-oriented thinking and initiative.

A cutting-edge technological working environment creates an enrichment of the work, a high level of job satisfaction and a contribution to the personal development of employees.

5. Consistent quality

I wouldn’t say that this is a specific advantage of a mobile cobot… it’s a general advantage of robots in general as compared to humans.

The work that a Cobot carries out is always the same.

The Mobile Cobot works constantly with the same force and along the same programmed route. This means that the quality of the performance is always the same.

Unlike humans, cobots are very accurate. Some cobots can perform actions with an accuracy of 0.1 mm. In addition, a cobot will never deviate from its actions and will always perform tasks with the same power. For example, tightening screws, this will always be done with the same tension and pressure which ensures consistency in quality.

Of course, you do not need me to explain the benefits of consistent production quality: better customer satisfaction, lower cost of production, etc.

6. Flexibility

Flexibility is one of the main and most obvious advantages of mobile cobots.

You already know that a mobile cobot is composed by a mobile autonomous base and a collaborative robot. Well, regarding flexibility, these two elements beat competitors in their own specific fields.

- AMRs are more flexible than AGVS (do not miss the article: Differences between AMRs and AGVs).

- COBOTS are more flexible than traditional industrial robots.

Collaborative AMRs perform natural navigation and they can be used to automate many aspects of the internal material handling without changes to the layout.

On the AMR you can, for example, mount different top modules such as robot arms, conveyors, shelf lifts to pick up carts, racks, pallet lifts, or other equipment on top to support specific workflows.

The flexibility also comes from its accessibility to workers with minimal robot training that can easily re-deploy the robot to a new task with minimal training and no programming skills required.

This is particularly important for manufacturers needing small automation tasks or that consistently process small production batches. Mobile cobots are easy to repurpose for new tasks. As a result, cobots can be used in different tasks in a single day saving the otherwise expensive liability of owning multiple traditional industrial robots.

Moving material autonomously from A to B has already been achieved. The challenge now is to pick and place this material on a higher surface or staging area. This is a key factor for a Smart Warehouse.

Cobots are the best solution for pick and place tasks. In this case, the cobots pick up an object and place it elsewhere. A mobile cobot can be useful if the drop-off location is very far away from the pick-up location, e.g. when picking orders from a warehouse of shelves.

7. Improved productivity

Let’s recap the advantages indicated above:

- Reduced downtime means more time producing products

- Easy and fast installation means more time producing

- Better use of space means better workplace disposal

- Improve Health & Safety working conditions means less absenteeism

- Consistent quality

- Flexibility in operations which allows constant readiness for new challenges

The main goal of robotization is of course to optimize a process, i.e. efficiency. In other words, achieving the maximum goal with minimal costs.

When errors are minimized, employees have more time for other things, productivity increases, and ultimately this results in a better operating margin.

Setting up and equipping a mobile cobot obviously requires an investment, but in the long run, it saves money and results in a greater profit.

As explained, there are a bunch of reasons driving to one purpose… yes, the purpose that drives business: Productivity and thus money.

Unlike humans, collaborative robots do not get tired, distracted, and do not stop to have a coffee. Theycan work 24/7.

Mobile cobots offer better use of space and less operator interventions, extending their productivity benefits over time.

With mobility, collaborative robots achieve an even higher degree of flexibility and autonomy, creating efficiencies in tasks such as material handling and allowing human workers to focus on more important priorities.

All these benefits lead to a more efficient and competitive system.