Autonomous Forklifts Explained for Beginners

Autonomous fork trucks are disrupting the material handling industry. Forklift AMRs represent a step further compared with traditional AGV Forklifts. What does make Autonomous Forklifts different?

Autonomous fork trucks are disrupting the material handling industry. Forklift AMRs represent a step further compared with traditional AGV Forklifts. What does make Autonomous Forklifts different?

I'm Alfredo Pastor ... in the last years we've seen a new army of autonomous robots coming... one of the most impressive is the autonomous forklift: easy to install, reliable and efficient.

I'm Alfredo Pastor ... in the last years we've seen a new army of autonomous robots coming... one of the most impressive is the autonomous forklift: easy to install, reliable and efficient.

In this article I explain the main topics related to these outstanding robots and I link to nice and useful resources and donwloadables ... do not miss them and read until the end 😎.

Unlocking Potential: A Guide to Autonomous Forklifts

What is an AMR Forklift Truck?

Also known as AMR Forklift, an autonomous forklift robot is a type of robotic driverless forklift or self-driving forklift that complies with two specific requirements to have the "right" to be called “autonomous” and to differentiate from an agv robot.

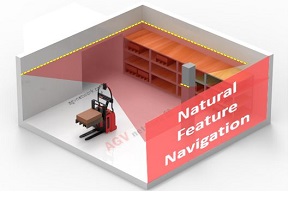

✅ First, it must perform autonomous navigation (also called natural navigation).

With natural navigation, the forklift navigates "looking at the environment" 👀 and does not need any type of infrastructure or hardware like reflectors for LGVs or magnetic tapes on the floor.

There are several technologies under the "autonomous" umbrella: Vision Guided Vehicles (VSG), Ultra Wide Band (UWB) or vehicles using LiDAR sensors for contour-based navigation (typically known as SLAM).

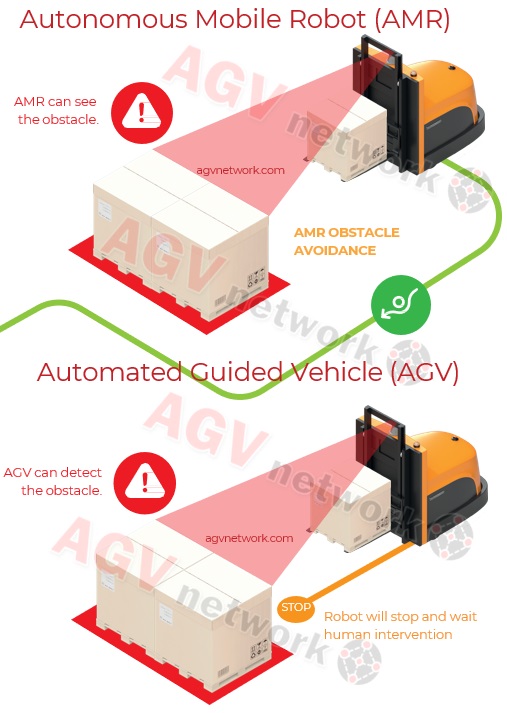

✅ Second, to be “autonomous”, it must be able to decide autonomously different guidepaths by its own and should avoid obstacles.

These two characteristics represent the main (but not the only) difference between agv and amr.

|

At the end of the day, an autonomous forklift is just an autonomous mobile robot (AMR) “soul” in a forklift “body”. |

Top Advantages of Autonomous Forklifts

Let's take a look at the main benefits that autonomous forklifts will bring to your operation:

Autonomous forklifts mitigates workforce shortages effect

Transporting material in a factory or warehouse involves a significant amount of manual effort, especially for three-shift operations. Even without considering the safety concerns, it is a difficult job, which is material handling with manned forklifts have a high turnover rate and frequent call-offs.

As if this weren't terrible enough, trends show that the labor shortage is worsening.

|

“5.5 million more job openings for warehouse operators than there are workers available to fill them” according to the Labor Department. |

Of course, Autonomous forklifts bridge the labor shortage gap by reducing the dependency on workers.

Moreover, working with a cutting-edge technology like an autonomous forklift, makes the job more appealing increasing the retention rate.

Autonomous forklifts reduces operator costs

Let's be honest. 🤷🏽♂️ If you install an autonomous forklift, you'll immediately calculate the savings in terms of salaries.

Check this out: Average Hourly Earnings of all employees, warehousing and storage in the US (check: https://www.bls.gov/ )

As you can see, the average cost of a worker is around $23 per hour. Even worse... check the trend...

You know, moving material is a non value-added task, so autonomous forklifts allow you to save manpower direct costs, especially in three shifts operations.

Autonomous forklifts increase Safety

Autonomous forklifts are crammed with sensors and technologies that prevent them to run into people or things.

Simply put... there are safer than manned operated forklifts, specially if they compy with the latest safety standard 3691-4.

Check this numbers below, amazing.

As a matter of fact, OSHA estimates that the quantity of manned forklift-related accidents alone are around 100,000 every year

- 90% of forklifts are involved in an accident throughout the span of their lifetime

- 11% of forklifts in the U.S. are associated with an accident every year

- 80% of forklift accidents include a pedestrian

Well, autonomous forklifts avoid these accidents.

💡 By the way, safety is a very wide topic. If you wish to learn further, I suggest to download my dedicated whitepaper packed with nice illustrations:

Of course, it's free for agvnetwork's registered members ????

Of course, it's free for agvnetwork's registered members ????

| Click here to download the whitepaper |

Autonomous forklifts are consistent

Consistency is essential! Sure, an autonomous forklift won't be able to handle material as quickly as the greatest forklift driver in the bay, but it will be consistent throughout the working hours.

And the finest forklift driver can accomplish considerably more if he can supervise a pair of autonomous forklifts rather than driving a single forklift. He can perform numerous chores at the same time with some innovative thinking!

With autonomous forklifts handling the heavy lifting and repetitive duties, your staff can concentrate on more critical activities that need creative thinking, assuring optimal production.

Tons of benefits

There are many other benefits to autonomous forklifts, let me list some of them

- Less human error

- More traceability

- Better Inventory accuracy

- Improved employee satisfaction

- Minor worker strain and fatigue

- Reduced indirect costs

What are the different types of Autonomous Forklifts?

In general, there are two types of autonomous forklifts.

✅ Autonomous Pallet Jacks. For floor-to-floor material handling.

✅ Autonomous Pallet Stackers. For stacking material up to 7 ft (2 m).

Typically, autonomous forklifts are limited to low racking heights up to near 7 ft (2 m) for maximum payload around 4.000 lbs (2 ton).

One of the drawbacks of the autonomous navigation is they have a wider positioning tolerance compared with Laser Guided Vehicles.

Racking heavy material at significant heights requires very tight positioning tolerances that can be achieved only with Laser or Inductive wire agv navigation systems.

🙋🏼♂️ It is also true that natural navigation is improving very quickly and there are several companies supplying reliable autonomous navigation software so we’ll probably see autonomous forklifts reaching higher racking heights step by step.

How much do an autonomous forklift cost?

- Autonomous Pallet Jacks price is near $45.000-$60.000

- Autonomous Pallet Stackers price is near $60.000-$80.000

Ok, ok... these numbers by themselves are useless 🤷🏼♂️, there are many other variables to consider. Check this article for further info: Autonomous Forklift Cost - Main Drivers

The cost of an Autonomous Forklifts does not differ so much from a traditional laser guided vehicles. The components in the vehicle are almost the same and the navigation technology costs is similar.

The difference in price relates to commissioning and programming the whole mobile robot system. Autonomous forklifts are easier to install so the total system cost is typically lower than a laser guided system.

What are the safety standards applied to the Autonomous Forklifts?

Even if they are classified as “autonomous” this type of vehicles is not covered by the R15.08 - Safety Standard for Autonomous Mobile Robots.

Autonomous forklifts are covered by the International AMR Safety Standard EN 3691-4:2023.

Who are the Autonomous Forklifts companies?

There are several and good suppliers. Here below you have some of the top autonomous forklift manufacturers:

- SMARLOGY

- AGILOX

- BALYO

- F3 DESIGN - NIPPER

- MOVIGO

- SEEGRID

- VECNA

Do not forget to visit the AGV Network Showroom, you can select robots by type, payload, lifting height, etc. Here you have a snapshot... this is what you can find in the showroom... nice stuff.

Autonomous Forklifts Resources

Finally... if you wish to learn further about forklifts and mobile robots, I suggest to download agvnetwork's Robotic Forklift Guide where you can discover all the AMR Forklift Manufacturers together with tons of info about driverless forklifts.

Of course... It's free... ????

| Download The AGV Forklift Guide |

|

Keep on learning What is a Laser Guided Vehicle? Top Autonomous Mobile Robots Applications R15.08 - Safety Standard for Autonomous Mobile Robots (AMR) AMR Robots in Warehouses Types and Applications |

Written by Alfredo Pastor Tella (agvnetwork editor).

Written by Alfredo Pastor Tella (agvnetwork editor).

Follow me on LinkedIn... let's create a mobile robot community to discuss and learn about these outstanding systems.