12 Types of Amazon Warehouse Robots

These are the main robots used by AMAZON to boost its warehouse operations:

These are the main robots used by AMAZON to boost its warehouse operations:

- KIVA

- HERCULES

- PEGASUS

- PEGASUS X-SORT DRIVE

- XANTHUS

- BERT

- ERNIE

- CARDINAL

- SPARROW

- PROTEUS

- SCOOTER

- KERMIT

Keep on reading to discover all the amazon robots one by one.

Many things have changed since Amazon's acquisition of Kiva PODS. Nowadays, it is difficult to find something that has not been thoroughly reviewed. In an Amazon warehouse, everything is mechanized.

Following packing, an automated labeling system and miles of conveyor and sortation devices are installed. There are many warehouse robots, strategic, and engineered for maximum efficiency. All of Amazon's Warehouse robotics are listed here.

But remember... Amazon is not the only one manufacturing outstanding warehouse robots... discover more than 200

What Robots does Amazon Robotics use?

| Robot | Picture | Description |

|---|---|---|

| Kiva |  | Goods to Person robot near 75x60x35 cm. Payload 450 kilograms (1000 pounds). Speed of about 5 km/h. |

| Hercules |  | Similar to Kiva but with 3000 lbs lifting capacity (near 1500 kg) |

| Pegasus |

| Pegasus replaces the original Kiva but 19 cm thiner. Payload 560 kg |

| Pegasus X-Sort Drive |

| Using the Pegasus as the base, different attachments can be added on top. X-Sort Drive, a half-meter belt of conveyor, is an example of such an attachment. |

| Xanthus |

| Hybrid Robot. Xanthus succeeded Pegasus. In June 2019, Amazon MARS presented this robot for the first time. This drive unit can also carry pods, but it can be used with a variety of attachments. |

| Bert |

| Bert is mobile and can navigate the warehouse with the help of cameras and sensors. It can be ordered and programmed to transport packages within a facility by a worker. |

| Ernie |  | Ernie moves around the stack using a robotic arm. It lifts totes from the stack to place them in front of workers. |

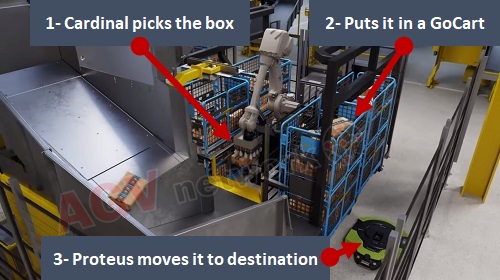

| Cardinal |  | Cardinal is an autonomous workcell able to pick boxes and accurately put them into GoCarts. From here, another AMR like Proteus can move the cart to next destination. |

| Sparrow |  | Presented in Nov '22, Sparrow is a cutting-edge picking robot able to handle goods with different curvature and size. |

| Proteus |  | The first AMR fully developed by AMAZON able to navigate safely and collaborate with humans. |

| Scooter |  | Scooter is an automated tractor that tows empty totes around, Kemet specializes in returning empty totes. |

| Kermit |

| Kermit is an automated guided cart (agc) with magnetic navigation where decision points are tags on the flooor tha indicate if it should change direction, speed up or slow down as it travels along. |

Aren't fancy these amazon warehouse robots names?

How many robots does Amazon have?

On June 2023, Amazon has declared to have 750,000 robots in its distribution and fulfillment centers.

Other Warehouse Robots similar to Amazon's ones?

Visit agvnetwork's showroom to discover dozens of mobile robots

Amazon's agv robots appear to impact the company's efforts to provide more consistent income for its warehouse workers, but their roles in safety and efficiency are undisputed.

From only a few years ago to today, Amazon has grown far beyond that physical and mechanical warehouse you used to know.

Now, Amazon is taking automation one step further. The company uses a multitude types of warehouse automation technologies to improve productivity and profitability at its warehouses, distribution centers and fulfillment centers.

Amazon Pods

When you enter into an Amazon fulfillment center, the robots may not look like your typical sci-fi expectations, but they pack more than human hands could ever achieve.

At the fulfillment centers, Amazon robotic pods transport items to humans to be picked up and packaged (what is called Goods-To-Person).

Using this robot-human alliance, humans can pack around 300 to 400 products per hour instead of just 100.

The "Amazon Bot System," is continuously optimized to increase package handling and delivery efficiency.

This robotization started when Amazon acquired Kiva Systems, one of the pioneers of warehouse robots, in 2012.

Just like the scenes in The Jetsons where robot neighbors will assist their human house-mates, Amazon Kiva robots were expected to automate more than 40% of their operations in fulfillment centers.

The fleet of Amazon Automated Guided Vehicles include:

The Original Kiva

Amazon Robotics has been referred to as Amazon Robotics by the public, despite everyone knowing that the company's real name was Kiva Systems. The original Kiva is the robot that Amazon was supplied by Kiva, back then called DU 1000. It has a drive unit that could lift 1000 pounds (near 450 Kg).

The Original Kiva was the starting point for Amazon's love affair with robots.

Amazon original Kiva

The Original Kiva is tasked with moving shelves/pods for storage and picking.

KIVA robot measures approximately 1x1m and is about 75 cm long and 60 cm wide. In addition to being 35cm tall and weighing around 110kg), this device can lift 450 kilograms (1000 pounds). This robot meets a speed of about 5 km/h.

The Hercules

Kiva Systems introduced Hercules in 2007. When it was initially introduced, it was called the DU 3000, as it could lift 3000 pounds.

Heavy-duty lifting is possible with this device. Hercules functions in the same way as its smaller cousin (the DU1000), but it can lift much more weight. All dimensions of the robot are larger, so the pods are similarly larger. The pallet-pods also have legs so the robot can go underneath.

The Pegasus

Taking its name from the mythical winged horse, Pegasus replaces the original Kiva. The original Kiva still performs the same job, moving pods around.

However, it stands 19 cm tall, 10 cm lower than the original. Now you can store stuff 10cm deeper. As well as lifting 560kg, it is slightly more powerful than its predecessor, which could lift just 450 kilograms. It also costs less since it has only half as many parts!

Since the company would have to spend a lot of money replacing all original Kivas, it won't likely happen. The Pegasus may, however, be used in new fulfillment centers.

Specifically, Amazon wants to use it close to cities. They want to locate more fulfillment centers close to high population densities for delivery within two hours or even with one-hour times.

However, being near a big population means everyone else wants access to the site, which becomes very expensive. To reduce investment costs, the Pegasus makes it easier to store more stuff in a warehouse. Amazon has already installed several hundred Pegasus robots.

Amazon sorting robots in the warehouse

The Pegasus X-Sort Drive

Using the Pegasus as the base, different attachments can be added on top. X-Sort Drive, a half-meter belt of conveyor, is an example of such an attachment.

There is no pod-carrying function for this robot, and its purpose is completely different. Rather than sorting and delivering completed parcels, the device carries them to shipping.

A worker labels the package and places it on a robot. It moves it to the relevant chute according to the truck that the parcel should go to. On the conveyor belt, the parcel is simply dropped into the chute.

As a concept, this is nothing new, and videos from China from a few years ago show how warehouses used similar sorting technology. Nonetheless, this is a very nice implementation.

Amazon benefits from increased flexibility thanks to this. Pegasus X-Sort Drive allows much more flexibility to change the fulfillment center than tangled murky conveyor belts do now. Amazon claims that it has also halved the number of mis-sorting errors.

But due to the increased number of robots moving around on this Pegasus, Amazon had to create a new traffic control system to program even more traffic rules.

Amazon Hybrid (G2p+Sorting sorting robots)

Unlike the main sorting robots, hybrid robotics systems include two kinds of robots: SCARA style and LBRY/Parabolic Trough Robotics.

The systems can place eight separate packages in an hour, including packages from small bins with packing peanuts. At Amazon fulfillment centers, Xanthus is the lone child in the family of hybrid robots.

Xanthus succeeded Pegasus. In June 2019, Amazon MARS presented this robot for the first time. This drive unit can also carry pods, but it can be used with a variety of attachments.

Compared to the original Kiva, it is cheaper, easier to use, and thinner. Having fewer parts means there is less maintenance required.

Attachments for the Xanthus can be varied. In the center is the base unit. Its left and right sides contain x-drive units, similar to the Pegasus's X-Sort drives, which sort packages into chutes.

Amazon Picking Robots

Picking is the next robotics generation and Amazon is increasing efforts to have reliable piece picking robots.

Sparrow Picking Robotic Arm

Amazon claims that Sparrow employs AI and computer vision to pick items..

The robot can firmly hold objects thanks to suction cups attached to its surface. In the past, robotic arms could pick up boxes of varying sizes but uniform shapes.

Sparrow can handle objects of varying curvature and size.

The technology behind is not just picking up the same objects over and over and moving it with tremendous precision, as was shown with earlier robots.

AMAZON claims that its robotic arm can identify roughly 65% of their product range.

Even while the introduction of warehouse robots sometimes raises fears about the future of human employment, Amazon is certain that Sparrow will "take up boring activities," freeing up workers' time to focus on more meaningful tasks.

Cardinal

Cardinal was announced on 2022 June the 22nd. It arrived to improve operator's ergonomic working conditions by reducing of twisting and turning motions.

Cardinal is a robotic arm able to handle packages up to 50 pounds (near 22 kg). Thanks to its advanced artificial intelligence (AI) and computer vision is able to choose one package out of a pile. But not only, it can also read a label and wisely place it in a cart (what Amazon calls "GoCart").

After that, a mobile robot like Proteus can safely transport it to its destination.

Other Amazon warehouse robots

With Amazon's growth comes a rapid rise in the demand for new warehouse robots for new applications. Thus, the company has been on the hunt for warehouse robots for the past few years.

Proteus- The AMAZON Autonomous Mobile Robot

Proteus is the first autonomous mobile robot developed by AMAZON. It has been announced on 2022 June the 22nd.

Proteus Robot is the first AMAZON's "autonomous" robot, because until now, AMAZON has used G2P robots with QR code navigation that is not considered under the "autonomous" umbrella.

If you do not know how do AMRs differ from AGVs, check this article: Differences between automated guided vehicles and autonomous mobile robots.

Proteus instead, is able to navigate and moves through AMAZON's facilities using advanced safety, perception, and navigation technology developed by Amazon.

The robot has been built to be able to work and move around employees and not in confined to restricted areas.

In fact, proteus will act like and autonomous guided cart, moving carts what will reduce the need for people to manually move heavy objects through facilities.

Bert and Ernie

Bert and Ernie are front-loading warehouse robots used in the Amazon fulfillment centers, designed to handle an estimated 40% of all Amazon's orders.

Ernie moves around the stack using a robotic arm. Ernie takes totes off of a robotic shelf and uses a robotic arm to deliver it to employees, so they can remain in a more comfortable, stable, and ergonomically friendly position.

It lifts totes from the stack to place them in front of workers. By easily reaching low down or high up, Ernie reduces the risk of injuries caused by employees making strenuous movements.

Totes can be removed from shelves by Ernie, which then hands the goods over to human workers. Workers in warehouses don't have to bend over or crouch down for totes. Although robots like Ernie don't make processes go faster, they reportedly make employee safety a priority.

In contrast, Bert is mobile and can navigate the warehouse with the help of cameras and sensors. It can be ordered and programmed to transport packages within a facility by a worker.

By eliminating manual labor, workers focus on more important tasks instead of pushing or driving the machine.

Currently, Bert is a bit too small to transport bulkier and heavier items, but a larger version might be designed after testing. Various items can be moved by Bert through a warehouse by itself, including smaller objects, eliminating the need for additional trips by employees.

Scooter and Kermit

The other robots in Amazon warehouses are Scooter and Kermit. These two robots are designed to move carts.

In the long run, the company believes these robots will eliminate the need for workers to move empty boxes across facilities. The robots help Amazon employees devote more time to activities requiring critical thinking by reducing physical demands.

Scooter and Kermit are both autonomously guided vehicles.

Kermit is an automated guided cart (agc) with magnetic navigation where decision points are tags on the flooor tha indicate if it should change direction, speed up or slow down as it travels along. The company plans to have Scooter at each of its facilities pulling carts around the warehouse.

Scooter is an automated tractor that tows empty totes around, Kemet specializes in returning empty totes. The company says it has made its facilities safer by using Scooter and Kermit.

Amazon Automated Forklifts

To boost productivity, Amazon has been expanding its forklift fleet at a rapid pace. And the robotic system plays an integral role.

Once an Amazon employee scans an item for delivery, the forklift lifts it to drop it at its destination. Or it might take a pallet from the delivery truck to a designated slot within the warehouse.

In 2019 Amazon signed a deal with French robotics company Balyo. A warrant representing up to 29 % of Balyo's capital was handed to Amazon in exchange for Balyo products.

Today, BALYO supplies automated forklift systems (stackers, pallet jacks, VNAs, etc), tow tractors, and other robotics systems to Amazon, which has significantly advanced the latter's warehouse automation endeavors.

Amazon benefits from having forklifts that run around the clock, never quit and operate without fatigue. Human drivers may not be completely replaced for several years to come. Still, the technology is currently on its way to reducing costs and expediting what is already a fairly efficient process.

Are you interested in Robotic Forklifts? Check my full guide.

Do not miss agvnetwork's free guide listing more than 60 Robotic Forklift Manufacturers

| Download The AGV Forklift Guide |

In a nutshell

Amazon has a proactive approach to improving its operational performance and making processes more efficient. It takes a highly skilled and motivated workforce to implement innovative and disruptive systems, which is not easy for any company.

It seems that Amazon is always a step ahead its competition when it comes to robotics.

Amazon's robotic family is a clear indication of the determination by the company to save costs, deliver safer working environments and meet customers' needs in the shortest time possible.

Worryingly, though, these machines often share much of the same space and responsibilities as traditional warehouse workers.

|

Related articles...to learn more about Warehouse Robotics

Warehouse Automation Trends 2022 - Do you know what are the top 20 warehouse automation trends?

Warehouse Autonomous Robots - All the types of robots and their applications in warehouses

Where are AMR Robots used? - Autonomous navigation allows huge flexibility and incredible new applications

|

Written by Alfredo Pastor Tella (agvnetwork editor).

Written by Alfredo Pastor Tella (agvnetwork editor).

Follow me on LinkedIn... let's create a mobile robot community to discuss and learn about these outstanding systems.