AGV Wireless Charging? Manufacturers? Cost? Advantages?

Fast, efficient, clean, flexible... these reasons are leading agv inductive charging to conquer the mobile robot industry. Discover how does the contactless charging work and how does it help to increase your mobile robot fleet productivity.

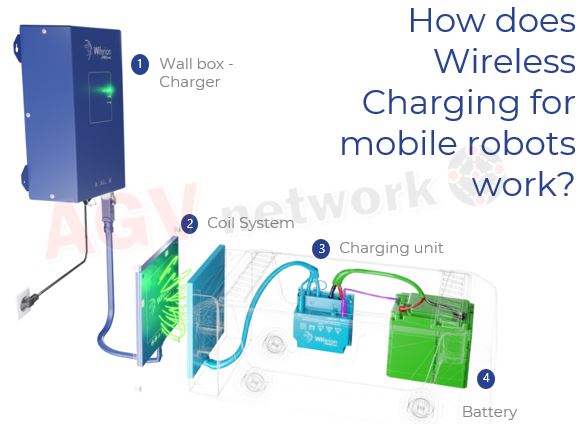

How does Wireless Charging for AGV work?

With an inductive wireless charging system AGVs can perform contactless battery opportunity charging.

In other words, power is transferred to the agv battery without any contact between the vehicle and the charging pad. How is it possible? Let me explain you 👇🏽

This picture is taken from the whitepaper: Mobile Robot Batteries and Charging Systems

Basically (and before explaining the technology behind), and AGV with a contactless charging system counts on:

(1) The charger to supply power from the grid to the robot. This is the same for other types of agv charging systems.

(2) A power transfer coil system: With a stationary active fixed coil on the floor (or on a wall) and on a mobile passive coil on the mobile robot.

The active coil generates a magnetic field that induces an alternated current in the mobile coil. This current is used to charge the mobile robot battery (4).

We can find inductive charging solutions for typical 24 V or 48 V mobile robot vehicles, able to provide from around 20 Ah-500 Ah (0.5 kWh-32 kWh installed Energy storage).

My name is Alfredo Pastor ... and I love (literally) everything about mobile robots... .

My name is Alfredo Pastor ... and I love (literally) everything about mobile robots... .

In this article, I explain who are the main suppliers of wireless charging solutions, what wireless inductive charging for mobile robots is and what are the main advantages for AGVs and AMRs.

Wireless charging is a trending topic in the AGV and AMR industry. More and more AGV/AMR suppliers are slowly incorporating this technology into their robots...

I have recently run a pool in agvnetwork.com linkedin page and 42% of the agv&amr industry leaders consider that contactless charging will be one of the most interesting and powerful technological developments in the next years.

Data from AGV Network LinkedIn Poll

By the way... before going ahead.. do not miss agvnetwork's whitepaper with detailed information mobile robots batteries and charging systems.

| Click here to download the whitepaper |

AGV wireless Charging Manufacturers

The main AGV Wireless Charging Systems manufacturers are:

-

Wiferion

-

B&PLUS

- Buzzard by Multipowr

-

CaPow

-

Daihen

-

Delta Energy Systems

- Enersys

-

WiBotic

In the following table you can find some of the best suppliers of wireless charging technology for the AGV and AMR market.

All the information has been provided by the suppliers or has been copied from their webs. 🙋🏼♂️ I recommend to contact them for further details about their products and capabilities.

Mobile Robots Battery Charging Solutions

I will not go deep in this concepts because there's a dedicated article where I explain everything... step by step: agv charging systems. 👈🏽

Anyway, when we face a mobile robot project, we mainly have two different options:

- We can choose to perform what is called “opportunity charging” also called “online charging”.

- Otherwise we could opt for “battery replacement” also called “battery swap”

What is opportunity charging?

Opportunity charging, for mobile robots, permits batteries to be charged several times during its working hours.

The autonomous mobile robot or AGV goes to defined charging stations and performs charging while waiting for a new mission to be delivered. If the battery balance is properly calculated, the vehicle does not need to change the battery.

What is the battery swap strategy?

Well, it’s pretty simple. The mobile robot works with a single battery until it is fully drained, so it needs to be swapped with a fully charged one. Battery swapping can be done manually or automatically as needed or on a schedule.

How does Wireless Charging for AGVs work?

The opportunity charging can be performed with the classical “contact charging” electrodes or with the latest “inductive contactless charging”.

So, what is the difference between them❓ The point is pretty self-explanatory:

- In the “contact” charging there’s is a physical connection between the charging poles

- In the “wireless” charging the power transfer is done without any physical contact

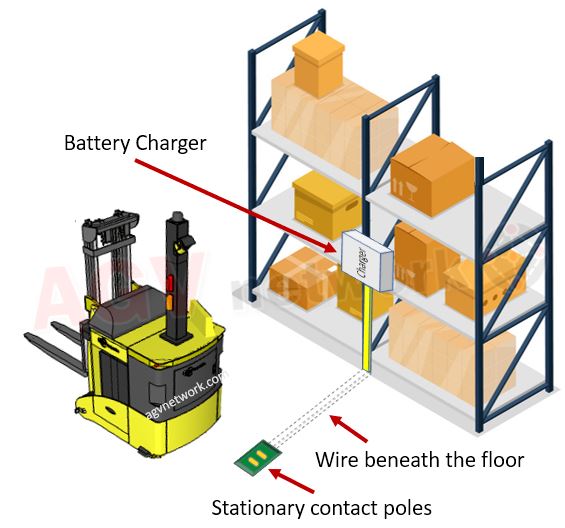

AGV contact charging system

AGV with contact charging poles

Typical contact charging poles

The agv with the onboard charging poles arrives to the charging station. The charging station is composed by the stationary contact poles and the charger.

The AGV moves down the contact poles, in general, thanks to a linear actuator.

The poles (onboard and stationary) touch. The charger verifies the voltage differential and starts the charging cycle.

AGV wireless charging system

The agv with the onboard charging "coil" arrives to the charging station. The charging station is composed by the "stationary coil" and the charger.

As soon as the onboard coil and the stationary coil overlap, the power is "magically" transferred without any contact thanks to the inductive principle.

What are the advantages to Wireless Charging For AGVs?

The main benefits of contactless charging technology are:

✅ High Efficiency 93%-95%

✅ Full Power Of High-Energy Streams Immediately After Start

✅ No Wear And Tear Or Maintenance As There Are No Contacts Involved

✅ High Mobile Robot Positioning Tolerance Compared To Contacts And Omnidirectional Charging

✅ One single wireless charging system can supply power to different vehicles and batteries

✅ Intelligent data transfer during wireless charging

The basics of Wireless Inductive Charging

The concept of wireless charging is simple: a magnetic loop antenna (copper coil) is used to create an oscillating magnetic field, which can create a current in one or more receiver antennas (receiver coils).

The “induces” word opens the doors to the Inductive Power Transmission.

Tesla demonstrated that an alternating current in a wire coil generated an alternating magnetic field, which, in turn, induced an alternating current in a proximity secondary coil.

By attaching a load to the secondary coil, the induced alternating current can, for example, charge a battery.

Under optimum conditions the process is efficient and facilitates easy charging.

Nevertheless, there are 2 factors that inherently influence the application performance related to Mobile Robots.

- The distance gap between the two coils. The flux drops rapidly with distance between the coils. It means that the closer the coils are, the more power transfer is achieved.

Consequently, the secondary coil must be placed as close as possible to the primary to intercept the most flux.

- The amount of energy that the secondary coil captures is proportional to the cross available section for the magnetic field.

The cross section depends on:

- The alignment (parallelism) of the two coils.

- The dimension of the coils

In addition to these “electromagnetics” basic concepts, we must mention that, in fact, there are two other inductive principles to remember.

- Non-resonant inductive transfer.

- Resonant inductive transfer.

So, if you want to know more, just check this link.

Here you have some important elements:

- In the resonant method, the primary coil and secondary windings are physically separated and tuned to resonate in order to increase the magnetic coupling between them.

- In the non-resonant inductive wireless charging method, the magnetic field flux rapidly falls when the distance between the coils increases. Non-resonant wireless charging is a good choice when you have to charge a single device quickly and efficiently on a dedicated charging mat.

- The magnetic flux in the resonant-inductive transmission is less affected by the distance. The problem is the low efficiency due to flux leakage.

In other words, if you want efficiency then choose non-resonant, if you want more flexibility and distances between coils, then choose resonant.

Of course, there are several AGV wireless charging technology suppliers, each of them has chosen its own path: resonant vs non-resonant.

Regarding AGVs and Autonomous mobile robots, the majority of suppliers offer non-resonant technology because it is able to supply more power faster. In other words, less time is needed for recharging your mobile robot, and more robots are availability for performing tasks, hence potentially less robots are needed.

What batteries are suitable for agv wireless charging?

Inductive charging is compatible with all types of battery 🔋.

- Open Lead Acid Batteries

- GEL/AGM Batteries

- Pure Lead Batteries

- Lithium Batteries

Lithium or Pure Lead batteries are the best option for AGVs or AMRs performing opportunity charging.

If we consider the high capacity power transmission of the wireless charging and its fast charging feature, it’s natural to think that the best battery technology is the Lithium one.

Lithium batteries are able to take advantage of all of the inductive wireless charging advantages.

- For a given depth of discharge (DOD), Lithium batteries grant more recharging cycles and thus more life.

- Lithium batteries are more efficient. Lithium battery efficiency is near 95% while in Lead batteries such AGM or GEL, are closer to 80-85%.

- While charging, you can pump more Amperes/hour without compromising battery life.

💡 By the way... do not miss this article where we explain the main types of batteries used by the automated guided vehicles.

What Is The Main Disadvantage to Wireless Charging For AGVs?

The main drawback for contactless AGV charging is the initial cost.

Initial investment is relatively high compared to traditional contact opportunity charging.

💲 Granted, initial investment is higher. However, as a business case, you have to take into consideration several factors. Check agvnetwork whitepaper about Mobile Robots Cost. You will find a lot of useful info, including the differences between wireless charging and other charging systems.

Download the AGV Cost Estimation Whitepaper

To be honest, the prices indicated above are not 100 % comparable because there menay other features included in the wireless charging system.

If you want to check the potential number of mobile robots with the wireless charging solution compared to contact charging solution, do not miss agvnetwork EXCEL AGV Cost Calculator. You can freely download it from the resources area.

For example, one of the main differences is the charger price but in the contactless charging system, the charger is more than "just a charger".

It delivers data and is plug and play into a single phase wall plug for the 3 kW System (no addition transformer, DC converter, etc…).

Total Charging System Performance: We have seen that inductive charging is more efficient . So, instead of having a 3kW charger you will probably only need a smaller one or you will need less time for charging.

If your AGVs need less time for charging they will have more time to accomplish missions, so less number of AGVs needed in the warehouse.

Of course, this feature will represent an advantage under certain conditions and depends on the total number of AGVs. If you have an AGV system with 2 AGVs, it will be difficult to reduce it to 1 AGV just because you installed a wireless charging system.

If you have an AGV system with 10 AGVs, you may be able to reduce it to 9 AGVs with an installed wireless charging system. Of course, these numbers must be analysed and completely depend on your specific project.

When calculating the total operating costs, we have to take into consideration the cost of the kWs/h for charging and the maintenance cost of the “contact” opportunity charging over the years. This calculation is more complex, and the wireless solution is a better solution compared to traditional contact opportunity charging.

Cash flow is limited 💲

So, convincing someone about a higher initial investment is a hard task. You have to think about it from a long-term business investment. You should always perform a detailed analysis to understand if wireless charging could represent a real advantage to your company’s needs.

|

Related articles AGV Battery Charging Systems Comparison. What's the best? AMR wireless charging benefits What are the Types of Battery for Automated Guided Vehicles? AGV Price - What are the key cost drivers in an AGV System? Vehicles, Commissioning, Service. Discover them all. |

Written by Alfredo Pastor Tella (agvnetwork editor).

Written by Alfredo Pastor Tella (agvnetwork editor).

Follow me on LinkedIn... let's create a mobile robot community to discuss and learn about these outstanding systems.