What is an Automated AGV Reach Truck?

Simply put, is a robotic driverless reach truck. Well, it is not so simple.

Simply put, is a robotic driverless reach truck. Well, it is not so simple.

My name is Alfredo Pastor ... In this article I will explain you what the main specifications of the automated reach trucks are, who are the main suppliers and, at the end of the article... how much do they cost... but, for doing this, I have prepared a business case... so it is more useful.

My name is Alfredo Pastor ... In this article I will explain you what the main specifications of the automated reach trucks are, who are the main suppliers and, at the end of the article... how much do they cost... but, for doing this, I have prepared a business case... so it is more useful.

What is an AGV Reach Truck?

A self-driving reach truck is a narrow-aisle, right-angle stacking truck designed for unit load handling typically used in racking operations.

It is the king of the warehouse bots, at least the king of the lifting robots in the warehouses.

Autonomous Reach Truck by Smarlogy

The reach truck is an specific type of robot forklift conceived to operate in narrow aisles and, together with the Automated Very Narrow Aisle Trucks, they are the best machine for storing and retrieving pallets in racks.

If you wish to know more about these "lovely" automated machines... you can freely download "The Robotic Forklift Guide", including a list of more than 60 manufacturers.

Do not miss agvnetwork's free guide listing more than 60 Robotic Forklift Manufacturers

| Download The AGV Forklift Guide |

How does a robotic reach truck look like?

If you're looking for an automated reach truck, you will find two different robots.

✔️ The first option is to have a manned vehicle that is transformed into an automated one. In this case, the robot keeps the manned vehicle chassis including its cabin, so you have the chance to drive it manually or automatically

✔️ The second option is to have have a fully new automated machine without the driver cabin. Something like this

In both cases, they are designed with two outer legs that help distribute the load weight, and a single set of wheels in the back.

Reach trucks are a smaller than the counterbalanced forklifts and they perform better in warehouses with narrow aisles and tighter spaces.

What are the typical specifications of the AGV Reach Trucks?

In the table here below, I summarize some of the main specifications of the automated reach trucks.

| Technical Specification | Value |

|---|---|

| Minimum Aisle width (distance between pallets) | 2900-3000 mm / 9,5-9,8 ft |

| For euro pallet 1200x800 mm | For euro pallet 1200x800 mm |

| Max racking height | 11 m / 430' / 36 ft |

| Load capacity | 1600 kg / 3.530 lbs |

| Reduced capacity at max height | 1100 kg / 2.425 lbs |

| Vehicle Speed forward | 2 m/s - 386 ft/min |

| Vehicle Price | $100.000-$180.000 |

| Navigation Type | Laser navigation and possible combination with natural navigation |

Of course, please, consider this data as an indication and you are warmly suggested to contact your supplier for more precise details.

What can Reach Truck AGVs do in a warehouse?

Picking-Dropping material from-to racks

Of course, picking and dropping pallets from/to racks is the main application of the automated reach trucks in warehouses.

The width of the corridor depends on the agv’s chassis dimension and the load length.

In general, the Automated Reach Trucks need 2,9 or 3 meters corridors (9,5 – 9,8 inches) to be able to pick-drop 1200x800 mm pallets safely.

The manned reach trucks instead, need around 2,7 - 2,8 meters (so something less than their automated brothers).

Take into consideration that depending on the speed of the vehicle, the agv must consider a safety area around itself.

In general, the safety area while performing the turning manoeuvre varies from 0,3 m to 0,5 m depending on the vehicle speed and load weight.

Do not miss this article where I explain the different “risk” or “hazard” areas for AGVs as described in the standard ISO 3691-4:2023.

💡 If you wish to have a deep understanding of AGV Safety Systems, do not miss the Mobile Robot Safety Handbook... tons of info: Standards, Legal framework, Robot Validation, Environment Risk Assessment... 👇

| Boost your safety Knownledge |

Racking tolerance:

A and C) Sideways tolerance: minimum 75 mm:

B) Vertical tolerance: minimum 100 mm

D) Back-to-back (pallet-to-pallet ) tolerance min 150 mm

Picking-Dropping material from-to buffer lanes

Reach Trucks can also handle buffer lanes on floor.

This is a typical operation when a manned forklift load/unload leaving/arriving trucks.

When the operator unloads a truck, he can leave the pallets on the floor composing buffer lanes.

In this case, the tolerances are near 100 mm for X and Y1.

As you can see, it's true that reach trucks can manage this type of buffers but ideally it would be more convenient to have a narrower vehicle.

The B1 dimension in an agv reach truck is around 1200-1400 mm compared to 800-1000 mm of other types of vehicles (counterbalanced, stacker, pallet jack). If you use a reach truck for this operation you'll waist floor space.

You must pay attention at the HAZARD AREA. The automated vehicle will have safety sensors so it will not run into anyone, but if there’s an operator on the lane he/she could stay trapped if there is not any scape area.

This HAZARD ZONES are explained in the ISO 3691-4:2023... but not only, we do also explain them in the AGV Network ACADEMY with more than 10 hr video dedicated to mobile robot safety... because we are all responsible!

| The Most Complete Course About AGV Safety |

Picking-Dropping material from-to conveyors

In the buffer lanes indicated above, the agv movement into the lane is really slow.

In some applications, it could be convenient to handle pallets from/to conveyors. In this case, the agv arrives always to the same picking dropping position and there isn’t need of going slow into the lane to “find” the pallet position.

Course: Mobile Robot Safety Course. Module "Environment Risk Assessment"

Reach trucks are fast and perform great in lifting operations, so having an “expensive” vehicle losing time in a buffer lane is a real pity.

On the other hand, conveyors are, surely, more expensive than simply putting a pallet on the floor.

Moreover, conveyors are fixed structures that could create flexibility issues in case of unit load variations over the time.

Imagine that you handle EUR pallets 1200x800, so you install a conveyor for this dimension and after two years you award a new business this US pallets 1200x1000. Maybe your conveyor is not wide enough.

How does an AGV Reach Truck Navigate?

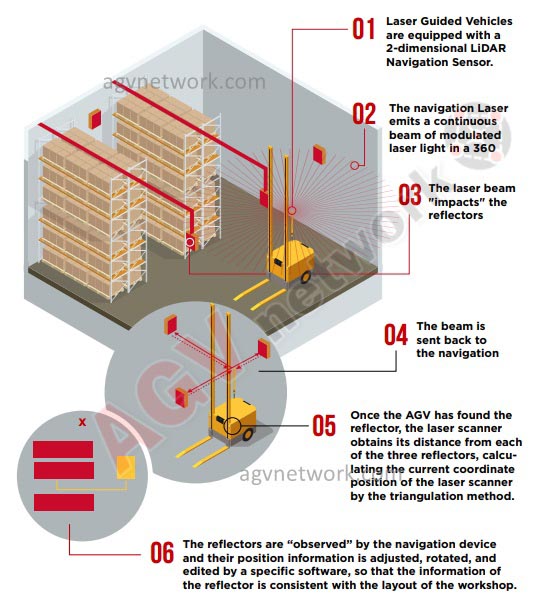

Typically, robotic reach trucks perform Laser Navigation, thus they are Laser Guided Vehicles.

In brief, the vehicle counts on a Navigation Device (let’s call it Laser Scanner) on top of a mast.

While working, this laser emits laser beams that impact in reflectors strategically deployed in the robot working area.

When the laser impacts the reflector, it comes back to the navigation device.

By combining at least three of these returned beams, the agv can calculate its positioning, speed, steering angle, etc.

This calculation is possible thanks to very complex algorithms that combine the info received from the laser scanner together with many other sensors, odometry and IMUs of the robot.

Why do Automated Reach Trucks perform laser navigation?

There are two main reasons:

1️⃣The first reason is Laser Navigation reliability. If the system is deployed properly, you can be sure that you will never have navigation problems

2️⃣ The second, and in my opinion most important, is its accurary. LGV’s can achieve +/- 5 millimetres (+/- 0.2 inch) positioning tolerance. This feature is very important if you wish to pick or drop material at 10 m high.

If you wish to know more about LGVs and navigation topics, I recommend you these articles:

|

About Navigation |

What the main advantages and disadvantages of reach trucks?

It depends on what other vehicle you are comparing the reach truck. - Reduced aisle width, so more warehouse capacity - Flexibility. Possibility to work in different areas - Limited payload capacity compared with counterbalanced - Need more aisle width compared to VNAsPros Cons

The benefits and drawbacks of a Reach truck compared to a Forklift Truck

- Depending on the design, lift trucks have a 35% smaller turn radius than forklifts. This allows them to work in narrower aisles.

- A reach truck forklift can reach higher shelving

- A reach truck forklift allows you to use a double deep pallet racking system

- A Forklift allow higher payloads

The benefits and drawbacks of a Reach truck compared to a VNA

- A VNA can work in 1,7 m wide aisles compared to near 3 m wide aisles of reach trucks. VNAs are designed to work inside warehouses that have a small amount of space and lots of stock.

- VNAs are clumsy “mammoths” out of the aisles. They are great in the aisle but require a lot of space for turning.

- Due to VNAs dimensions, they are more complex to integrate with other equipment like conveyors.VNAs cannot be used in lane buffers.

How much do AGV Reach Trucks cost?

An automated reach truck costs between $100.000 and $180.000 depending on the payload and lifting height.

I really love Reach truck AGVs... these vehicles are able to handle hundreds of pallets in a day requiring limited footprint for manoeuvres.

|

Understanding all the elements involved in such a calculation is complex, so do not hesitate to contact me in case you wish to have support for you next mobile robot project. I can help you to define the solution (type and number of vehicles), choose the supplier... and much more. ✉️ |

For calculating the payback, I will use the agvnetwork EXCEL ROI calculator, you can download it here:

AGV System Return On Investment

Of course, you should take the following numbers as an indication because your values could change depending on your project and your suppliers.

You are warmly welcome to contact me:

What is the Payback of an Automated Reach Truck System? …. Keep on reading…

The Business Case

The company “I’m not going to tell you the name” wanted to install an AGV Reach Truck System.

They company handled:

✅ 25 pallets per hour IN from conveyors

✅ 25 pallets per hour OUT to be deposit in a buffer rack

✅ 2 shifts

✅ 5 days a week

✅ The warehouse has 1300 pallet positions (not so big)

✅ EUR Pallet Max weight 1000 kg

✅ Max racking height 6,5 m

With this configuration the customer had 2 manned reach trucks.

How much does the manned solution cost?

An average price for a manned reach truck 1000 kg at 8 m is around 43.000 € (including charger and 2 open lead batteries).

If we want to calculate the PAYBACK of an AGV system we should consider the labor cost of the manned solution. Of course, the labor cost depends on your country.

In our case, let's say it is 18€/hour and we have to consider 4 drivers (to cover 2 shifts)

With this data, the annual labor cost is near 140.000€

At this point, regarding the manned vehicles, we could buy or rent them.

If we buy the vehicles, we could expect to pay near 86.000 € for both manned vehicles. Do not forget to add an annual maintenance cost, let's say around 10.000€ for both machines inlcuding some extra costs due to damages.

The customer could also rent the vehicles. In this case, for a 60 months lease and considering around 2% cost of capital, the monthly fee for each reach truck could be around 870€/month, in a full service contract (so including labor and spare parts for preventive and corrective maintenance).

If we consider the labor cost and the vehicles cost, after 5 years operation we could expect to pay around:

800.000€-850.000€ with the manned solution.

What about the AGV project?

If you wish to know the total cost of an AGV System, you have to take into consideration several cost elements:

- The vehicles: Type, specs... and number... yes, typically AGVs are slower than manned vehicles.

- The software: programming, mission management, route optimization, etc.

- The installation and commissioning: The technicians that will install and test the system

- Other devices: OPC, PLC for "hand shake" with conveyors, elevators, etc. Touch screens for mission generation, etc

If you wish to understand an AGV project cost structure, I warmly recommend to download this whitepaper:

| Click here to download the whitepaper |

Regarding the number of vehicles, it depends on the number of mission/hour, the distance, the curves, the manoeuvres, etc.

In general the software is a licence cost and the software engineers cost for programming your project, interface with the customer ERP, WMS, etc

The cost of installation and commissioning, depends on the project complexity, number of vehicles, etc.

In this case, the average distance of a mission is near 130-150 meters.

A: Pick "IN" pallet from comveyor

B: Deposit "IN" pallet on rack

C: Go to pick "OUT" pallet from rack

D: Deposit "OUT" pallet in Out Buffer Rack

E: Go to pick new "IN" pallet

All the missions where provided by the customer's WMS. So when the reach trucks picked the pallet from the conveyors (A), they already knew in which positions they had to leave them (B).

The only problem was that the out buffer on racks was also handled by manned vehicles that picked material to be shipped on trucks. So there was some "traffic" concern.

How much does the AGV Solution cost?

Vehicle Cost: Near 115.000€

Nb of Vehicles: 3 AGVs with around 95% saturation (based on distance, nb of missions, pick-drop conditions, etc)

Project Cost: Near 110.000€ (based on project complexity)

Total AGV project cost: 456.000€

Of course, AGVs could be rented too... you can understand further with this whitepaper:

Financial costs, maintenance, best practices... what's important to know about AGV/AMR Rental?

Financial costs, maintenance, best practices... what's important to know about AGV/AMR Rental?

| Click here to download the White Paper |

Manned vs AGV comparison

With all the data indicated above, the customer had a payback of near 2,5 years... not bad

Yes... I know... I made it simple... it is not so easy... but I hope that this example has helped you to understand better how to calculate an AGV payback.

Of course, there are many things to consider: how to calculate the number of vehicles, what vehicle is the best, how to integrate with your erp or wms, potential layout modification...

Do not hesitate to contact me (or you supplier) if you wish to know further.

Automated Reach Truck Manufacturers

Automated Reach Truck for 11 m lifting with 3 m aisle width. Boost your warehouse performance.

The SMARLOGY AGV Reach Truck is an ultra-versatile autonomous vehicle able to handle multiple tasks in warehouses for storage and retrieval operations..

Main specs:

- Seamless natural navigation combining SLAM technology, IMUs, Laser Navigation.

- Possibility to combine several navigation sensors to garantee maximum reliability and tolerances.

- Lifting capacity up to 11 meters with different masts.

- Payload up 3.500 kg

- Ability to work on aisles 3000 mm wide

- Maximum picking/dropping accuracy with fork tilting and lateral positioning.

- Cold storage with special configuration for freezing environment

- Outdoor configuration

SMARLOGY CONTACT

More Automated Reach Truck Manufacturers

Written by Alfredo Pastor Tella (agvnetwork editor).

Written by Alfredo Pastor Tella (agvnetwork editor).

Follow me on LinkedIn... let's create a mobile robot community to discuss and learn about these outstanding systems.