AGV ROI - 101 Payback Guide for Automated Guided Vehicles

Thinking of investing in an automated guided vehicle (AGV) system? How long will take for your AGV system to pay for itself? How to calculate the roi for the agv?

My name is Alfredo Pastor ... I prepare many offers for mobile robot projects every week. Honestly, there are many variables to take into consideration and it's quite complex to have a definitive solution leading to a final value.

My name is Alfredo Pastor ... I prepare many offers for mobile robot projects every week. Honestly, there are many variables to take into consideration and it's quite complex to have a definitive solution leading to a final value.

If you wish to make your own calculation, I have prepared an excel Automated Guided Vehicle Return on Investment (ROI) Calculator that can help you to understand if your poject makes sense.

In this article, I show you a real business case example and I use the calculator, so you can learn how does it work.

What is the typical Payback of an AGV System?

- The payback of an AGV project is near 2 years for a 3 shift operation project

- Near 4 years for a 2 shift operation project

- Near 6 years for a 1 shift operation project

🤷🏽♂️ Ok, ok... there are many things to say here... let's see an example.

Example of Automated Guided Vehicle Payback Calculation with Excel Calculator

Probably, 💲 if you are thinking about implementing an AGV System is because you want to save money. AGVs involve both direct and indirect cost savings.

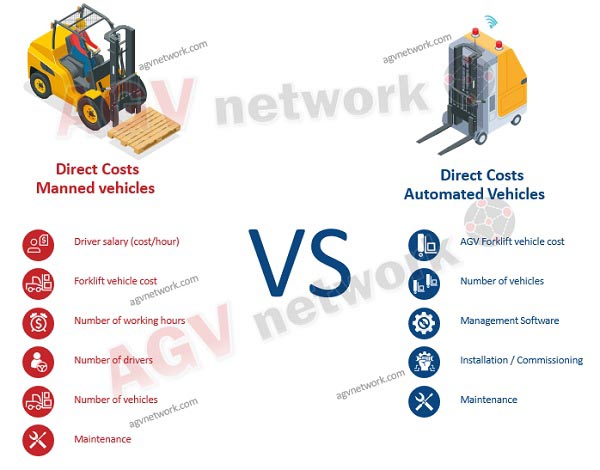

Direct costs are easy to identify. In general, AGVs substitute human operators and their equipment. The typical direct costs are:

- Hourly wages

- Overtime

- Type of Equipment

- Number of operators

- Number of equipments

- Number of working hours

There are other “soft", but crucial benefits of automated guided vehicles to be taken into consideration. These advantages are difficult to evaluate from an economical point of view. For example:

- Impact on safety—The reduction of accidents, incidents, and lost time results in significant savings.

- Flexibiilty—Fundamental AGVs that can be effortlessly relocated to where they are most needed provide added value in terms of agility.

- Enhanced quality—Decreased errors and damage contribute to improved profitability.

But, I know... it is difficult to put these numbers in an EXCEL.

Check this video where I explain these "soft" benefits.

For example, reduced costs can be related to damages, training, utilities, etc. Some other costs are even more complicated to evaluate like increased safety (Yes! AGV Robots increase safety).

Now, let's explain how to calculate an AGV Forklift System payback. For doing this, we will explore my downloadable Excel File: Free Download Area.

This calculator takes into consideration only the direct costs, but provides different values depending on the type of AGV Forklift, thus making an “apples to apples” fair comparison between the manned and the automatic systems.

The data provided by this calculator must be understood as an indication. All the prices and values are an average that could vary from case to case. I warmly suggest contacting your AGV supplier for a more detailed analysis.

First of all, you have to download the calculator: CLICK HERE TO DOWNLOAD IT

How to calculate an Automated Guided Vehicle System (AGV) Return on Investment (ROI)?

Cost of the Manual Solution

Type and Quantity Of Machines

First, we have to decide what kind of Forklift we need. In the EXCEL, you can select these vehicles: Pallet Jack, Stacker, Forklift Truck, Reach Truck or Very Narrow Aisle (VNA).

In our case, I'll consider a company having nr 2 reach trucks, with the following specifications:

The cost of these reach trucks is around 41.600€/each.

By the way... these are reach trucks...

Working Hours - Number of Shifts and Salaries

One of the most important things required to define an AGV System payback is the number of working hours or shifts.

💡 If you pay $100.000 for an AGV System, this cost is the "almost" the same if your system works for 8 hours or for 24 hours a day.

In the next table, you must indicate the number of working shifts per day and the number of working days per week. With these values we will know how much the AGV system will work.

In our case study, I will consider a standard 2-shift operation – 5 days a week. 📆

How many manned forklifts do you need per shift?

For example, if you have a warehouse with 2 manned reach trucks per shift, in our case, you will need 4 operators (4 for each shift).

What is the standard wage of your forklift operator?

Accordingly with the US Bureau of Labor Statistics, the averages cost of a forklift operator is near $21/hour. We'll consider near 20 €/h in our example.

This table automatically calculates overtime costs, for example night shifts, Sundays and provides an average labor cost/hour. In our case, 4 people would cosy around 153.600€/year to the company.

By the way, do not miss agvnetwork's Robotic Forklift Guide, with tons of info about self-driving forklifts (safety, navigation, sensors, etc)

Do not miss agvnetwork's free guide listing more than 60 Robotic Forklift Manufacturers

| Download The AGV Forklift Guide |

Total Cost of manual Operations

Let's come back to our case. The total cost of manned operations is composed by:

- Equipment cost

- Labor cost

- Maintenance cost, that depends on the vehicle type and the number of working hours

In our case we have as follows:

Do not miss this miniguide explaining what's behind an agv rental contract. 😉

| Click here to Download the Guide |

In order to calculate the monthly lease price/fee, you must input the interest rate and the leasing period. The leasing fee will depend on these factors and working hours, as well as the residual value at the end of the contract.

Cost of the AGV System

Before exploring this point, I recommend you to read this article: How much is an AGV? because it explains in detail the different elements of cost in an AGV system.

Basically, the AGV system cost is determined by:

- AGV cost (AGV Type and number of AGVs).

- Peripherals: Battery management system, plcs, etc.

- Management Software cost

- Commissioning cost (programming, deployment)

- Other costs: project management, documentation, FAT, etc.

Our calculator considers the AGV vehicle cost (including online charging station and battery) and a cost item called “Project Complexity”.

This calculator considers that the AGV Forklifts are slower than manned vehicles so you will probably see a higher number of AGVs compared with the number of manned vehicles.

At this stage, you should consider that on average, a manual forklift is substituted by 1,3-1,5 AGVs.

AGVs run fast but manoeuvres are slower and, overall, they are slower. Probably, your AGV supplier will tell you that AGVs are as fast as manned vehicles, but our experience says the opposite.

The item “Project Complexity” gathers other costs like peripherals, management software, commissioning, etc.

Project complexity is ranked from 1 to 5 and is weighted depending on the vehicle type, the number of vehicles, the number of picking and dropping positions, the mission management system, etc.

For example, our project considers a “Project Complexity” #4. It is a warehouse with 600 picking and dropping positions, all the missions are provided by the customer WMS (so the AGV only acquires the info “pick in A – drop in Z”).

As you can see, the number of AGVs required is 3, while the number of manned vehicles was 2.

Totally, you can expect to invest nearly €554.000 in your Reach Truck AGV System (including maintenance).

The AGV System Payback

In our example, the AGV system payback is 2 years and 11 months.

Conclusions about the AGV AMR payback calculation

Of course, calculating an accurate payback for your AGV system requires a much more detailed analysis. The payback depends on many factors:

- Vehicle type and number of vehicles

- Number of working hours

- Labor cost

- Project complexity

In fact, related to manned vehicles, if we want to be more accurate, we should consider some additional cost related to “soft benefits of AGVs”: Safety, product damages, etc.

Good luck with your AGV project!

Do not hesitate to contact me at

Written by Alfredo Pastor Tella (agvnetwork editor).

Written by Alfredo Pastor Tella (agvnetwork editor).

Follow me on LinkedIn... let's create a mobile robot community to discuss and learn about these outstanding systems.