Are Warehouse Drones the solution for Inventory Management?

Whenever there is room for optimization there is an automated solution. The warehouse business represents a huge opportunity for new technologies able to provide competitive advantages. Here they comes the warehouse drones.

Whenever there is room for optimization there is an automated solution. The warehouse business represents a huge opportunity for new technologies able to provide competitive advantages. Here they comes the warehouse drones.

Inventory Audit Autonomous Warehouse Drones (or simply ware drones) play a key role in smart warehouses thanks to sophisticated navigation and obstacle avoidance sensors.

My name is Alfredo Pastor,I have written this article because I'm very interested in this technology and I think that it will evolve and bring substantial advantages to the warehouse automation process.

My name is Alfredo Pastor,I have written this article because I'm very interested in this technology and I think that it will evolve and bring substantial advantages to the warehouse automation process.

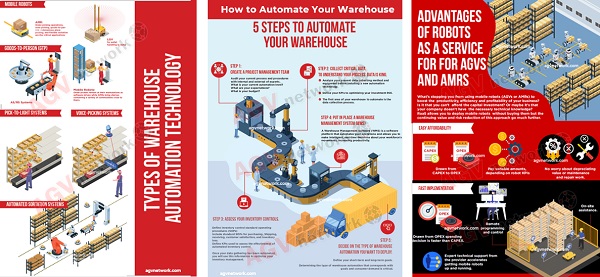

Drones are one of the latest warehouse automation trends aiming to reduce the non value-added tasks, but of course, there are few more advantages to warehouse automation than just costs; automation improves safety, workforce retention, customer satisfaction, etc.

Let’s discover how autonomous drones improve warehouse operations.

|

Table of Contents Inventory drones, the new autonomous flying frontier What are the main applications of drones in warehouses? Drones Obstacle avoidance technology How much do inventory drones cost? |

Do not miss the agvnetwork free guide with useful info and illustrations

| Download The Warehouse Automation Guide |

What are warehouse drones for inventory management?

Warehouse drones, also known as UAV (unmanned aerial vehicles), are aerial robotics platforms used in Smart Warehouses for inventory management.

Warehouse drones perform tasks such inventory audit, cycle counting, stock finding, etc.

They fly autonomously, identify and count the material stocked in the warehouse and compare it with the data stored “virtually”, enabling safe and cost saving inventory operations.

Checkout this short video that gives a clear idea of these awesome flying vehicles.

I have prepared an infographic with nice illustrations about the warehouse drones. You can download it for free in this link

| Click here to download the infographic |

Inventory drones, the new autonomous flying frontier

Most of the warehouses and distribution centers struggle for twice-yearly or quarterly full-counts of their inventory.

Moreover, to properly track the inventory, many companies perform cyclical counting, thus a more frequent inventory management activity where a small sample of inventory is counted instead of the entire population of inventory.

It means a lot of work and costs that not all the companies can afford.

All these headaches lead to introducing drones into warehouse management

Drones are a new kind of warehouse robots technology that has been recently developed thanks to the improvements in the technology required to fly safely and the capacity to “navigate” reliably indoors without a GPS signal.

To fly safely in warehouses, the drones must have robust obstacle and collision avoidance systems, capable navigation sensors, and robust on-board processing power.

The key difference of warehouse drones from normal ones is the ability to fly without GPS signals. GPS is unavailable for the drones because they must fly in indoor areas where the GPS signal could be weak or nonexistent.

Because they fly indoors, warehouse drones don’t have to comply with aviation regulation rules such Beyond Visual Line Of Sight (BVLOS), better known as Part 135 certification, in the United States.

A common misconception that tends to crop up is that drones can completely replace manual stock takes. This is neither possible nor intended.

It is more reasonable to view drones as another kind of tool used in warehouse automation, a powerful one for minimizing inventory variance and cycle counting issues.

Recognizing these opportunity for warehouse drones, numerous companies have sought to pursue it – not only Silicon Valley startups and university spinoffs, but even those who were offering RFID, WMS or other solutions to the supply chain industry.

Warehouse Drone Companies

These are the main suppliers and manufacturers of warehouse management drones.

What are the main applications of drones in warehouses?

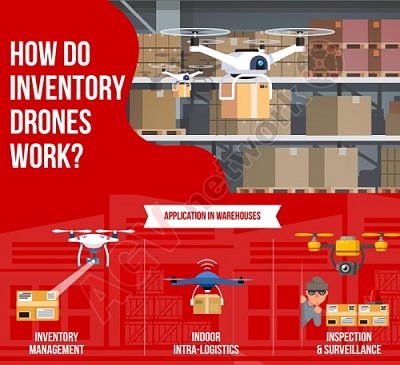

The indoor drones have three main potential applications in warehouses:

- inventory management,

- indoor intra-logistics

- inspection & surveillance

Considering the current technology limitations in power supply and payload capability, indoor intra-logistics and inspection & surveillance don’t have the same high potential as inventory management.

How do drones enhance the efficiency of warehouse operations?

These are the main applications of drones for Inventory Management:

- inventory audit

- inventory management

- cycle counting (Cycle counting is a popular inventory counting solution that allows businesses to count a number of items in a number of areas within the warehouse without having to count the entire inventory. Cycle counting is a sampling technique where the count of a certain number of items infers the count for the whole warehouse.)

- item search

- buffer stock maintenance

- stock taking (Stock taking is the counting of on-hand inventory. This means identifying every item on hand, counting it and summarizing these quantities by item).

Tasks like stock taking are often done annually or by the end of the fiscal year.

Other inventories like cycle counting (so counting a partial amount of a warehouse’s inventory) are performed on a more frequent basis, even daily or weekly by experienced inventory staff.

Because the cycle counting is carried out by people, it is obviously slow, labor-intensive, dangerous, expensive, and error prone. Drones instead can optimize this process dramatically.

The main objective of using drones for inventory management are to increase the inventory accuracy, decrease labor costs and minimize dangerous tasks for the workforce.

Inside the warehouse, a drone performs autonomous flights as it is equipped with highly developed sensors.

It is fed with the real-time inventory info by the warehouse management system.

The drone travels inside the warehouse according to the digital map prepared before the flying task starts. The drone software helps to plan the best possible flight path.

How do inventory drones work?

In order to use indoor drones for inventory management, drones must be able to work properly and safely. There are several critical features to accomplish with:

- On-board processing power: to allow the drone to run algorithms locally (on-board), even with poor network connection that would limit the capability to get instructions from the central management system during flight

- Vision system: the camera system on the drone should be able to retrieve data from inventory, and should be able to identify racks, aisles, bulk lanes to locate itself in the warehouse.

- Collision avoidance capability/system: the drone needs this system to ensure the safety to fly within the warehouse.

- SDK/API: the data collected by drone will not be stored on the drone brain or software. This information must be integrated into exist inventory management system, so applicable SDK/API interface to exchange data is essential to provide inventory managers with warehouse insight

With these technologies available, the drones can help improve inventory management with three modules:

- Data Collection: the autonomous drones sit in a particular area in inventory when idle. The battery of the drones can be charged when the drones are parked waiting for a new mission. The drones wake up on a pre-defined schedule, take off, hover in the warehouse, capture the data, and return to the nest to recharge themselves.

- Data Processing: after collecting the data, the drones upload the data to the cloud. The server processing the data uses Artificial Intelligence, Machine Learning, Neural Network algorithms to get better analytical insight of the inventory

- Insight Delivery: the insight report can be sent to inventory manager, or integrate into customer’s Inventory Management System.

The Fleet Management Software enables multiple drones to fly autonomously, hover accurately and land precisely.

The competence of computer vision, Artificial Intelligence, Machine Learning, high-quality video processing, cloud connectivity, robotics, auto-pilots, and numerous other technical capabilities will determine the success or failure of a warehouse drone system.

Warehouse Drones count on Deep Learning techniques along with computerized visuals and optical systems. This combination of advance tech allows the drones to fly around in a warehouse unimpeded. The space inside a warehouse is marked by X, Y or Z coordinates.

The drone checks inventory labels with its visuals and identifies the packages that are being searched for or getting counted. The drone is able to map inventory as per the known coordinates.

- The information collected by the drone, mostly digital images, is analyzed instantaneously to make a calculation.

- The count generated is evaluated with the records of the WMS (Warehouse Management System).

- The comparison brings out an exception report which is checked by warehouse experts.

- By viewing the digital images, the calculations are confirmed and then the WMS is updated.

- The WMS gets closer to the real inventory count.

There are four key factors that drive the success of autonomous drones in warehouse management: reliability, stability, scalability, and affordability of the whole drone system.

The ability of software to enable fully autonomous indoor navigation and automatic scanning of barcodes, QR codes, alphanumeric labels, RFID tags, etc.

The operational, commercial, and strategic fit between inventory drone solutions and the ground realities of warehouse inventory management.

Of course, warehouse drones have potential skills to resolve further operational tasks, such as:

- How pallets, cartons, cases are stored on racks,

- How storage space gets optimized using narrow aisles and tall racks,

- Management of various barcode sizes, colors, fonts, alignments & conditions,

- Inventory turnover optimization

- Hours available for inventory counts (eg. DCs vs. retail stores),

- Degree of autonomy for drone operations (flight, charging, scans, missions, etc.)

How do Drones avoid obstacles?

If a drone crashes into a tree, it’s considered a bad thing, but if it crashes into a person, it could be catastrophic.

Same as the Autonomous Mobile Robots that perform natural navigation, for a drone, to detect obstacles and then take action to avoid the obstacle (whether to stop, go around or above the object) involves many complex technologies working together in harmony to create an integrated system that decides what to do and how to do it.

This entails sensors, software programming which include mathematical modelling, algorithms, machine learning, and aspects of SLAM technology.

These various obstacle avoidance sensors feed the data back to the flight controller which is running obstacle detection software and algorithms.

What sensors do warehouse drones use?

Drones typically have some of these sensors:

Stereo Vision

Stereo vision works in a similar way to 3D sensing in our human vision. Stereoscopic vision is the calculation of depth information by combining two-dimensional images from two cameras at slightly different viewpoints.

Ultrasonic (Sonar)

An Ultrasonic Sensor sends out a high-frequency sound pulse and then times how long it takes for the echo of the sound to reflect back. With this info it is possible to calculate the distance to an obstacle.

Time-of-Flight

Time-of-Flight camera consists of a lens, an integrated light source, sensor and an interface. It is able to capture depth and intensity information simultaneously for every pixel in the image making it extremely fast with high frame rates. ToF cameras are also highly accurate.

LiDAR

A lidar sensor calculates distances and detects objects by measuring the time which it takes for a short laser pulse to travel from the sensor to an object and back, calculating the distance from the known speed of light.

Others are Infrared or Monocular Vision

Check this link if you want to know more about a drone’s collision avoidance systems.

How much do inventory drones cost?

The cost to deploy a warehouse automation system depends on many factors. Though the price of the most powerful type is near $1000, the total cost of the system depends on the several factors:

- The size of the warehouse or distribution center

- The desired frequency to run the cycle counting and stock taking

- The expected accuracy of the counting

What are the Advantages to warehouse drones?

Warehouse managers will absolutely benefit from applying drone-based warehouse automation.

The main benefits of drones for warehouses are:

-

Reduce resources for low-value tasks

- Better ROI, buy reducing overhead and staffing costs

-

Improve ability to scale quickly

-

Lower human error

-

Be more proactive in inventory management

-

Build ability to gather data upon request

-

Improve KPIs

- Such as cycle counting frequency, worker safety, inventory accuracy, slot utilization, etc.

What are the Disadvantages to warehouse inventories drones?

However, there are still some concerns regarding the new drone solution adoption. Drones are still trying to gain acceptance in the industry.

- Automation is not a new concept for warehouse management, but drone-based automation hasn’t got many proven track records yet. Most solutions are still in a validation stage.

- Not fully automated yet. Without full autonomy, the system won’t behave much better than people expected.

- Drones can’t scan small objects well. This might impact the inventory accuracy

- Existing WMS are not necessarily drone-friendly. To integrate drone into WMS could be a big challenge

|

Related articles Warehouse Automation Technology - Do you know what are the top 21 warehouse automation trends? Warehouse bots - All the types of robots and their applications in warehouses Applications of Autonomous Robots - Autonomous navigation allows huge flexibility and incredible new applications |

Written by Alfredo Pastor Tella (agvnetwork editor).

Written by Alfredo Pastor Tella (agvnetwork editor).

Follow me on LinkedIn... let's create a mobile robot community to discuss and learn about these outstanding systems.