Automated Pallet Jack- What is a pallet robot?

Small, fast, accurate… and... unmanned. This article explores the Automated Pallet Mover robot, keep on reading to discover how do pallet mover robots improve internal material handling transportation.

Small, fast, accurate… and... unmanned. This article explores the Automated Pallet Mover robot, keep on reading to discover how do pallet mover robots improve internal material handling transportation.

What is an AGV pallet jack?

A Pallet Mover AGV, also known as a fork-over AGV is a type of pallet truck agv robot conceived to transport palletized loads in manufacturing facilities.

These pallet moving robots are easy to deploy beacuse they do not require any infrastructure modification and, typically, they can be inlcuded in your standard process flow without any variation. If you have a manned pallet jack moving pallets from A to B, there's a good chance that you can substitute it by an automated vehicle with the consequent advantages of agvs.

|

In this article I will explain you what the automated pallet movers are, how do they work, what are their main navigation methods and their safety systems,etc. |

Finally, I will let you know how much do automated pallet jacks cost. By the way, do not forget to register because at the end of the article I have linked two excel cost calculators and a whitepaper dedicated to the AGV cost calculations.

|

Table of Contents

What is an automated pallet mover? Autononous pallet movers manufacturers Self-driving pallet robots specifications |

Basically, an automated pallet lifter is a self-driving pallet jack able to drive and navigate by itself.

This AGV application allows limited vertical movement of the load, reaching pallets on racks or shelves at low height or in floor-to-floor operations.

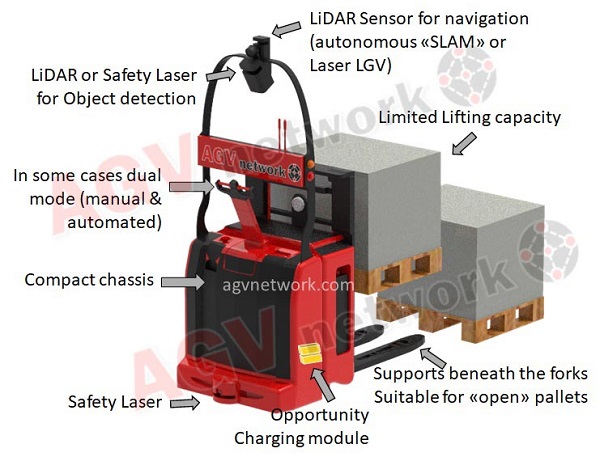

Autonomous pallet movers are the “smallest” of the forklift AGV category.

These autonomous pallet robots have stabilizers located beneath the forks. These stabilizers allow reduced AGV dimensions, weight, and a tight turning radius, ensuring great maneuverability.

Autonomous Pallet Movers are suitable only for Single-Face Pallets due to their fork stabilizers.

If you need to handle Double-Face pallets, you need a counterbalanced or outrigger forklift agv.

Just a moment... do not miss the free 50 pages guide about AGV Forklifts ...

Listing more than 60 Robotic Forklift Manufacturers

| Download The AGV Forklift Guide |

Automated pallet mover manufacturers pictures and videos

AGV Pallet Mover - Typical Specifications

FORKLIFT AGV TYPE PALLET MOVER Racking Warehouse MINIMUM AISLE WIDTH (Distance between pallets) 3,6 m/140'/11,8ft MAX SPEED FORWARD 2 m/s - 386 ft/min LOAD STOCKING HEIGHT 1,5 m / 60' /4,9 ft MAX LOAD CAPACITY 1.500 kg /3.300 lbs

What is the AGVs pallet trucks load capacity?

These kinds of vehicles typically have a 1-ton capacity (near 2,200 lbs) even if we can find vehicles reaching 3 tons (6,600 lbs).

What is the robotic pallet jack truck lifting capacity?

Regarding lifting height, the typical stacking height of standard vehicles is around 1.5 m (5 ft) but there are vehicles able to reach 3 m (10 ft).

Under this category, there are the pure “pallet movers” that are automated pallet jacks able to lift only few inch/cm to stack the pallet from floor. This kind of pallet moving robot is typically used in “floor-to-floor” transportations.

How fast is a robotic pallet mover?

The typical max speed is 2.0 m/s (386 ft/min) max.

How do automated pallet movers navigate?

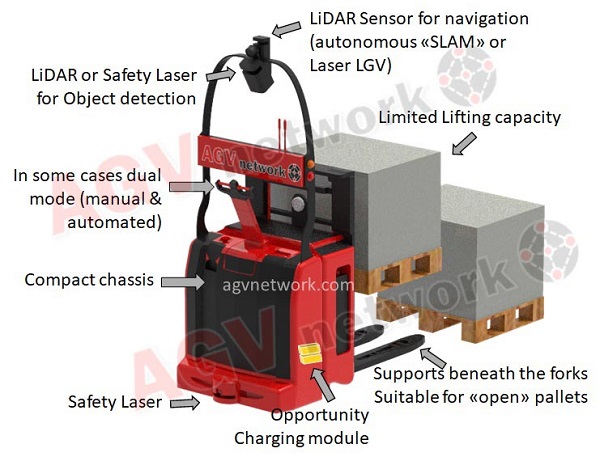

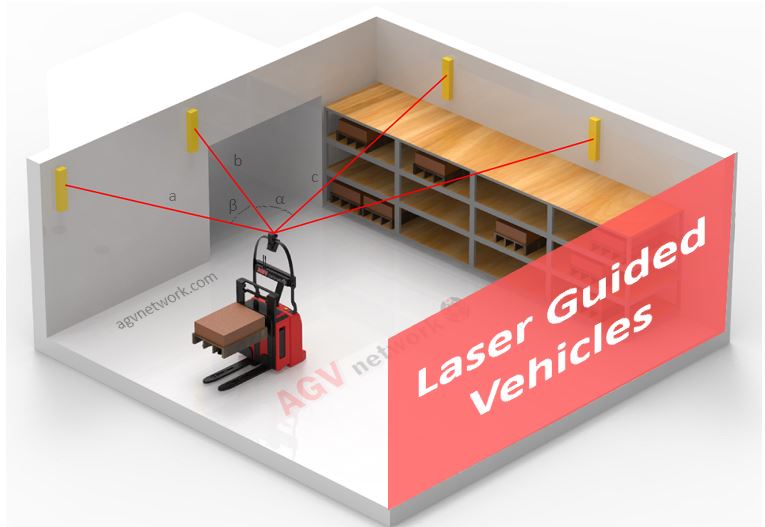

Some years ago, automated pallet movers were only LGVs so vehicles with Laser Guided Navigation having a LiDAR Navigation Laser (let’s call it a Navigation Device) positioned on top of a mast that interacts with targets positioned in the AGV working area.

The Navigation device sends rotating laser arrays 360 degrees around.

These arrays impact several reflector targets. Reflectors are reflective tapes or cylinders that send the laser array back to the laser navigation device.

LGV acquires at least three of these laser arrays feedbacks to calculate its positioning following very complex algorithms.

Recently, more and more AGV suppliers are implementing Autonomous Mobile Robot Navigation (also called natural navigation) rather than Laser Navigation because it is much easier to install and it is easier to perform route modifications once the system is installed.

These pallet trucks are known as Autonomous Mobile Robots (AMR) rather than AGV.

AMRs perform “free” navigation, so trackless navigation without need of hardware installation such wires, tapes, reflectors.

It means that the AMR is not “bonded” to any guide and navigate because they identify and map the surrounding area. They “see” walls, columns, shelves, everything and they navigate with this info.

There is a lot of literature about AMRs and about their differences compared to AGVs. If you want to know everything about this topic, do not miss this article AMR vs AGV.

If you're interested in this topic, I suggest to download the following free whitepaper.

| Click here to download the whitepaper |

AGV Pallet Mover Safety

Same as other AGVs or AMRs, these self-driving pallet movers must comply with exigent Safety Standars. The AGV Safety Standard in the US is ANSI/ITSDF B56.5-2019 and in EU EN ISO 3691-4:2020.

These mobile robots count on different safety elements that are divided in two categories, the active safety elements and the passive safety elements.

The main AGV Active Safety devices or AGV Safety Sensors are:

- AGV Safety Laser scanner or AGV collision avoidance system. AGV pallet movers count on non-contact sensors such as safety laser scanners. They can mount one, two, three, four, or more safety lasers depending on the project itself.

Front Safety Laser, to ensure safety conditions in “forward” operations, when AGV travels at high speed.

Safety Laser (or simply an object detection LiDAR or ultrasonic sensro) on the mast that targets diagonally to the floor. It is used to detect suspended loads.

Backward Safety Laser that is used while running backwards and during unit load deposit or removal.

- Contact Bumpers for stopping AGVs

- Emergency Stop Buttons

- Safety PLC

While the most important passive safety devices are:

- Warning Lights

- Audible Warning/Alarm Signals

- Signs on AGV Vehicle

Do not forget to consult this article that will provide you with some key concepts to help you understand what is behind an Automatic Guided Vehicle safety system and how could this safety system interact with the rest of AGV working area.

You can also download agvnetwork.com whitepaper about AGV Safety with lot of detailed info about the safety topic.

| Click here to download the whitepaper |

How much does a pallet moving robot cost?

Typically, a pallet mover agv costs around $55000. There are some chinese suppliers offering floor to floor autonomous pallet movers at around $30000.

Of course, this is the cost of the vehicle that depends on several factors such lifting height, payload, navigation technology, battery type, etc.

Nevertheless, I try to provide some indicative values depending on the vehicle specs.

- A Floor to floor (1000 kg - 2.200 lbs) with Laser Guided Vehicle navigation, costs around $40000. If we had Natural feature navigation it would cost near $50000

- If we add lifting height to near 60 inch (1,5 m), the same Laser Vehicle would cost around $55000. The Natural Navigation instead, would cost around $60000.

On top of these values, we must consider the total project costs, that is made of:

- The number of AGVs. It is a variable cost depending on the number of missions and distance travelled.

- AGV Management Software cost that is relatively fixed as the license fees do not change significantly based on the number of vehicles.

- Installation and commissioning cost that is the workforce cost related to the number of people and their number of hours required for the installation and programming.

- Peripheral costs related to the AGV system can greatly vary a project. There are many other elements to be taken into consideration in an AGV project, for example, PLC or OPC that will allow your system to communicate with the environment (robots, lifts, etc).

- Finally, you must consider the AGV maintenance cost, that of course it is not a part of the initial investment for the AGV system but that will absolutely define the total return of investment of the AGV.

Well, it is not easy to provide an accurate number. For this reason I have published these two excel tools (free for agvnetwork.com registered members) that will help you to estimate your automated pallet jack system cost.

Excel tools:

|

Excel Tools:

|

Additionally, I also recommend to download this whitepaper where I provide further details to help you to have an idea about the potential investment needed for your new Automated Guided Vehicle project.

| Click here to download the whitepaper |

If you enjoyed this article (hopefully yes...), I would appreciate if you could kindly share it.

|

Related articles

All the models and specifications of Automated Forklifts

What can Warehouse Robotic Forklifts do? AGV Pick Up Pallet Methods

AGV in Smart Warehouse - Discover the most innovative applications of mobile robots in warehouses

VNA AGV - List of Manufacturers and Characteristics of Very Narrow Aisle Robots |

Written by Alfredo Pastor Tella (agvnetwork editor).

Written by Alfredo Pastor Tella (agvnetwork editor).

Follow me on LinkedIn... let's create a mobile robot community to discuss and learn about these outstanding systems.