12 WMS Benefits: The Key to Warehouse Optimization

Are you looking to expand your warehousing operations? Check these advantages of a Warehouse Management System (WMS).

With the advent of e-commerce and rising customer demands, a well-organized warehouse is more crucial than ever.

A WMS may assist with streamlining procedures, improving accuracy, increasing production, and increasing customer happiness.

In this post, I'll look at the top WMS benefits and how they may help your warehouse operations.

1. Faster Inventory Turnover

Managing your inventory effectively is a must if you want to expand your business. Warehouse management software (WMS) allows you to manage your stock from receiving to shipping.

Too much stock might reduce cash flow, while not enough stock can cause backorders and angry consumers if not managed properly. But have no dread! When properly implemented, a WMS can completely alter the nature of your inventory management system.

Faster inventory turnover, shorter lead times, and less need for safety stock are all results of a well-implemented WMS. It's the equivalent of having a squadron of soldiers standing guard over your most prized possessions.

Say farewell to tedious counting and hello to a smoothly operating warehouse thanks to a state-of-the-art WMS. Imagine finally having all your inventory management wishes come true once you discover the key to success in the warehouse.

Related Content: Unlocking the Power of Warehouse Drones: The Future of Inventory Management

2. Warehouse workforce reduction

When it comes to cutting costs, a WMS (warehouse management system) can be a game-changer. A WMS can assist cut down on staffing needs by standardizing things like inventory transportation, picking procedures, and storage areas.

Several labor-intensive tasks, such as order picking and inventory tracking, can be automated with the use of a WMS, resulting in a smaller workforce.

Moreover, a WMS can optimize stock flow with an automatic replenishment system, reducing the need for staff to manually monitor inventory levels and reorder supplies.

Warehouses are like major cities, with stock moving in all directions at all times. This can make it difficult to keep track of what is coming in, what is being stored, and what is leaving. That is why it is critical to have a system in place for managing inventory turnover and efficiently storing products in order to reduce downtime.

If you're reading this article ... I guess you're interested in warehouse automation... check this out and do not miss my 54 pages free guide.

FREE guide with useful info and illustrations

| Download The Warehouse Automation Guide |

3. Better Stock Control

Nevertheless, manually tracking the location of every single product in your warehouse may be a difficult effort, and mistakes can be costly to your organization. A warehouse management system (WMS) can help with this. With a WMS, you can instantly locate and recover goods, ensuring that nothing gets lost in the shuffle.

Not only that, but a WMS gateway allows you to examine real-time information about your inventory levels and locations. This means you'll always know how much stock you have and where it is in your warehouse.

There will be no more guessing or going around looking for products with a WMS; everything you need will be at your fingertips.

4. Optimize Warehouse Space

A warehouse management system (WMS) allows you to track the location and movement of every item in your warehouse, recognizing which products have a higher turnover rate and keeping them in the most accessible locations.

Furthermore, by structuring your inventory to optimum storage capacity, you can reduce the requirement for safety stock while saving valuable space.

5. Better workforce retention

Consider your warehouse to resemble a buzzing beehive, with workers darting from one activity to the next. Nevertheless, as time passes, you discover that your once-busy bees are slowing down, and you're losing more workers than you'd want. What exactly is going on?

It's possible that your employees are dissatisfied with antiquated systems and a lack of enthusiasm. But don't worry, since a warehouse management system (WMS) can assist!

Your employees may benefit from simplified procedures and modern approaches that make their jobs easier and more productive with a WMS. This may enhance morale and keep your employees engaged, resulting in a more productive and loyal workforce.

A WMS can also assist to decrease physical strain on your workers by automating processes like stock replenishment and pick scanning, resulting in fewer accidents and lower staff turnover.

With the ability to effortlessly manage inventory and identify items, your employees may spend less time looking for products and more time getting things done.

6. Integrated Shipping Solutions

A WMS can assist you in easily planning inbound and outbound shipments while taking into consideration available workers and storage equipment.

You may optimize the particular day and time for merchandise to arrive, ensuring that everything is meticulously prepared. You may even arrange the receiving dock doors and outgoing shipping docks using WMS solutions, ensuring that everything goes smoothly.

Some WMS solutions can improve supply chain operations by connecting with transportation management systems (TMS).

Thanks to inventory tracking and packing choices, customers may also receive early notice of shipments and how their things are arriving. You may have a more direct interaction with your clients and provide advanced shipment alerts with a WMS system.

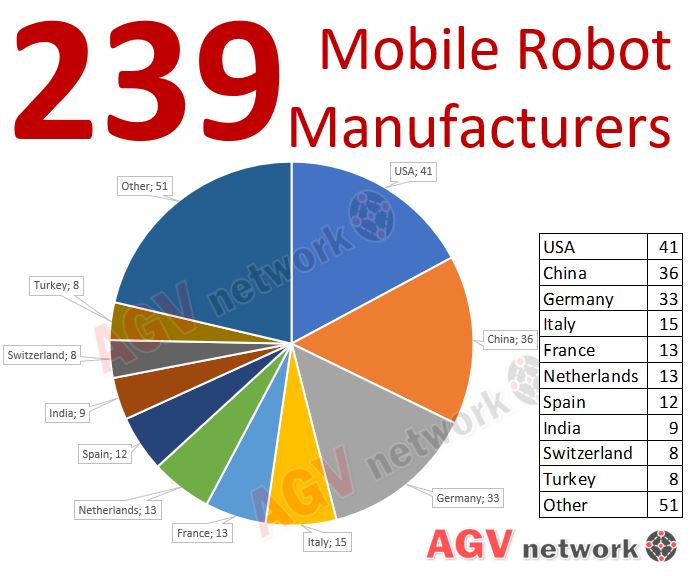

7. Opens the door for automation

Warehouse management systems provide a plethora of automation options for transforming your warehouse into a smart, efficient, and cost-effective business.

Paper-based labor may be substituted by digital activity using mobile phones, improving processes and maintaining data correctness.

Furthermore, automation adds potential for ongoing improvement to existing tasks, allowing for the introduction of more successful strategies.

There are several alternatives for automation, including robots, analytics-driven motions, and even artificial intelligence.

Warehouse management solutions are essential for realizing these opportunities. They are necessary for capturing, documenting, and transmitting warehouse activities. Warehouses may enhance operations and increase scalability by harnessing these capabilities, all while maintaining accuracy and consistency in their procedures.

Related Content: Transform Your Operations with the Latest Automated Warehouse Technology

8. A WMS allows Data Driven Decisions

To manage a successful business, you must be aware of how well your team is functioning in terms of product delivery to your clients. A sophisticated WMS offers a wide range of performance data to assist you in meeting that aim.

You may acquire important insight into what drives your income by keeping an eye on fundamental data such as total landed cost per product.

Completed inventory optimization is another essential statistic that may help you choose where to position stock in your supply chain and how to optimize your inventory budget.

9. Improves demand forecasts

One of the primary advantages of a WMS is that it gives businesses more insight into their inventory. This implies that demand estimates may become more precise, which is critical for maintaining appropriate inventory levels.

A warehouse management system (WMS) may assist warehouse managers in making educated decisions regarding how much inventory to keep on hand by assessing both current incoming and outgoing material flows as well as historical trends.

Unexpected changes in demand will never catch you off guard with a WMS. You'll constantly be aware of what's coming and will be able to alter your inventory levels accordingly.

10. WMS allows you to create strategies for specific goals.

A WMS may assist in the prioritization and optimization of all aspects of a project, from the most efficient warehousing routes to the best individuals for the task.

A contemporary WMS can guarantee that the correct personnel are in the right place at the right time, and that the warehouse layout is as efficient as possible, using labor predictions and floor simulators.

If a deadline must be met, a WMS can optimize everything to guarantee that merchandise is out the door and on its way to the client before the clock runs out. Consider a WMS to be a master conductor, ensuring that all aspects of the business are in perfect sync.

11. Strengthen Security

Individual user accounts in your warehouse management systems can help you transform your warehouse from chaotic to orderly.

These accounts provide accountability and reduce the risk of theft and other difficulties by creating an audit trail. It also assists you in identifying new training opportunities and methods to enhance personnel habits.

Say farewell to unlawful access and welcome to increased security. User-defined access levels guarantee that each employee sees just the information required for their job. This manner, you may protect your company's data while maintaining your competitive edge.

12. Finally, a WMS improves performance

Optimizing warehouse operations and performance requires Warehouse Management Systems (WMS). WMSs increase inventory management, processes, and productivity.

First, WMS systems give firms real-time inventory visibility, helping them label, count, and store things appropriately. Businesses may improve their bottom line by reducing overstocking, stockouts, and waste through better inventory control.

Second, WMS systems may automate picking, packaging, and shipping, allowing warehouse workers to focus on more important activities. Automating procedures reduces human error and boosts efficiency.

Third, WMS systems give firms data and analytics to discover inefficiencies and optimize procedures. Businesses may improve performance by using this data to assess inventory levels and labor productivity.

Fourthly, WMS systems may increase worker communication and cooperation by delivering real-time inventory levels, order status, and other vital information. This enhances staff collaboration and decision-making, improving warehouse performance.

Lastly, WMS systems improve customer satisfaction by fulfilling orders quickly and accurately. Businesses may satisfy consumer expectations and create a smooth shopping experience by managing inventory, order status, and delivery schedules.

In summary, a WMS may improve warehouse efficiency by increasing inventory visibility, automating repetitive processes, delivering important data and analytics, boosting worker communication and cooperation, and increasing customer happiness.

These solutions help organizations optimize warehouse operations and succeed.

|

Related articles

Web based WMS software: 11 reasons to abandon your WMS Server

The 20 Advantages of Warehouse Automation

|

Written by Alfredo Pastor Tella (agvnetwork editor).

Written by Alfredo Pastor Tella (agvnetwork editor).

Follow me on LinkedIn... let's create a mobile robot community to discuss and learn about these outstanding systems.