AGV in Hospitals. Autonomous Mobile Robots Disrupting Healthcare Automation

AGV systems in hospitals: From transport to service solution. Hospital are becoming like factories thus AGV systems will be playing an increasingly significant role to ensure optimal logistics availability and performance.

This article explains how AGVs improve Hospital Logistics, opening the door to “Hospital 4.0”.

Healthcare Transport Automation with Autonomous Mobile Robots

Boosting Hospital Logistics

AGV and Autonomous Mobile Robots are step-by-step entering into the healthcare industry. In fact, AGVs&AMRs are one of the main types of hospital robots.

AGV in Hospitals ? Why are AGV used in Hospitals?

There are several reasons driving this new situation:

- AGVs are becoming more affordable.

- Increasing human staff salaries

- Improvements in sensor technology for localization and navigation, for environment recognition and collision avoidance, for fleet management and material tracking, as well as for more detailed diagnostics of individual vehicles.

- Need to improve cleanliness (for example with Robotic Floor Scrubbers)

- Need to disinfect different environments (thanks to Disinfection Robots for Hospitals)

- Need to minimize Hospital Adquired Infections... so infections due to people moving in the Hospital.

These reasons (among many others) are driving the change.

Hospital AGV are becoming more and more convenient and are assuming non-value-added tasks such as pushing the 800 to 1,000-pound trollies that require a non-qualified workforce.

The AGV Robots for Hospitals play a significant role in daily operations and help staff to concentrate on their core care expertise to provide better patient care.

Thanks to sophisticated AGV Management Systems, AGVs lead to better:

- Patient Service

- Quality of care

- Operations Efficiency

- Business Results (yes, healthcare is a business)

What are AGV applications in Hospitals and Healthcare facilities?

We have seen it in many places, moving something from point A to point B is a non-value-added operation that can be done by a mobile robot.

In particular, the main AGV tasks in hospitals regard the transportation of:

- Meals from the kitchen to wards and the return of empty trays to the kitchen.

- Waste bins and trolleys. Full and empties management.

- Linen transportation (clean and soiled).

- Deliver trolleys/carts for cleaning and activate cart-washing systems.

- Sterile Supplies Transportation.

- Drugs and other supplies in the hospital (wards, theaters, pharmacies, laboratories etc).

Moreover, more people do move trolleys between different hospital departments and more possibilities there are of infections and illness propagation.

It is becoming mandatory to mitigate viral and bacterial spread. Mobile Robots do not get ill, do not cough and do not touch everything they found in their way.

Another special application is the UV Disinfection Robot, basically an autonomous mobile robot with UV emitter that kills viruses and bacteria.

Another important task is to keep floors constantly cleaned. Automous Floor Scrubbers are emerging to help hospitals and healthcare organizations to unlock consistent cleanliness and operational efficiency. In particular, they:

- Enhance patient, visitors and personnel experience

- Improve facility image

- Provide more frequent, consistent, and measurable cleaning

What kind of Automated Guided Vehicles are used in Hospital applications?

AGV types used in hospitals share the same design concept which have evolved over the years. In any case, each vehicle presents its own features depending on specific suppliers.

The standard configuration of hospital AGVs is an Automated Guided Cart (Hospital AGC) or Autonomous Mobile Robot (AMR), a wheeled base AGV on which a lifting platform is incorporated to carry out the load and transport of carts used in the distribution of goods.

There are other AGV configurations, for example the “L-shape design” that looks like a standard AGV pallet mover where forks have been covered or substituted by a customized structure for trolleys.

If you wish to know further about Automated Guided Vehicles types, I recommend you this article: What are the types of Automated Guided Vehicles?

In order to carry out loading operations, the AGV robot is located under the cart and the platform is lifted some cm/inch together with the cart ready to be transported.

Hospital AGV Cart

Even if Towing AGVs offer more transport capacity, they are not common in hospitals because they present some disadvantages such as:

- Lower maneuverability.

- They cannot use elevators.

- They need human intervention for hooking unhooking trolleys.

Ultraviolet Disinfection Robots - UV Robots for Hospitals

UV light is a proven technology to disinfect environments, and autonomous robots are a great base to transport these cleaning devices thanks to their advanced navigation technology.

The combination of ultraviolet light and autonomous robots makes this technology very interesting. The robot can autonomously drive around and position itself optimally in a relation to infection hotspots in any environment.

Automated systems used to kill harmful bacteria in places such as Hospitals, could improve patient safety, as well as protect hospital personnel and famliy visitors.

Shenzhen Wellwit robotics Co.,Ltd designs, manufactures and deploys disinfection UV Robots.

WELLWIT Video

Advertise here

Do not miss this article if you want to know more about Ultraviolet Disinfection Mobile Robots

What kind of Navigation Technology is preferred for Hospital AGV?

The main agv guidance method for Hospital Automated Guided Vehicles are:

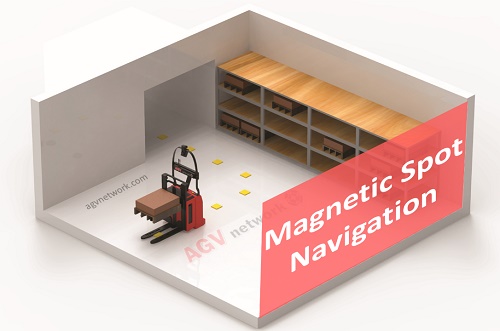

Magnetic Spot Navigation

AGVs can navigate following small cylindrical magnetic spots embedded on floor. Magnetic spots are installed each 250-500 mm (near 15 feet) creating a virtual grid.

The AGVs goes from a spot to the following one using sensors and controls such hall-effect sensors, encoders, counters, gyro sensor and other kinds of encoders to calibrate against steering angle errors.

Installation is quite invasive. It is necessary to make a small hole on floor where the magnet is positioned. After that, hole is covered by epoxy resin.

The main disadvantage is that it is necessary to leave the path free of obstruction. A maintenance person on a ladder changing a lightbulb would stop the AGV.

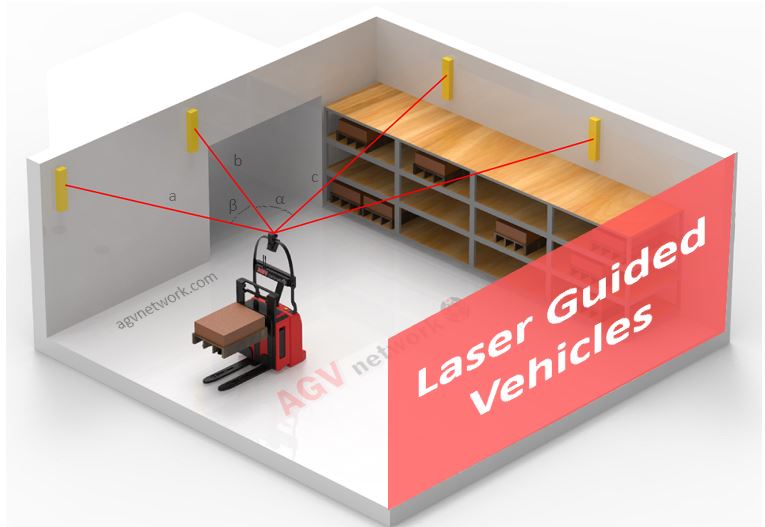

Laser navigation (LGV)

Each vehicle is equipped with a Navigation Laser that interacts with reflectors targets positioned in the AGV working area.

Reflectors are reflective tapes or cylinders around 60 cm high that are positioned in the facility structures such columns, walls, poles, etc. They return the laser array back to the laser navigation device.

The Hospital LGV acquires at least three of these array feedbacks allowing to calculate its positioning thanks to very complex algorithms.

This navigation method has low impact in infrastructures and it’s relatively fast to install.

Same as magnetic spot navigation, LGVs main disadvantage is that it is necessary to leave the path free of obstruction to avoid AGV stoppage.

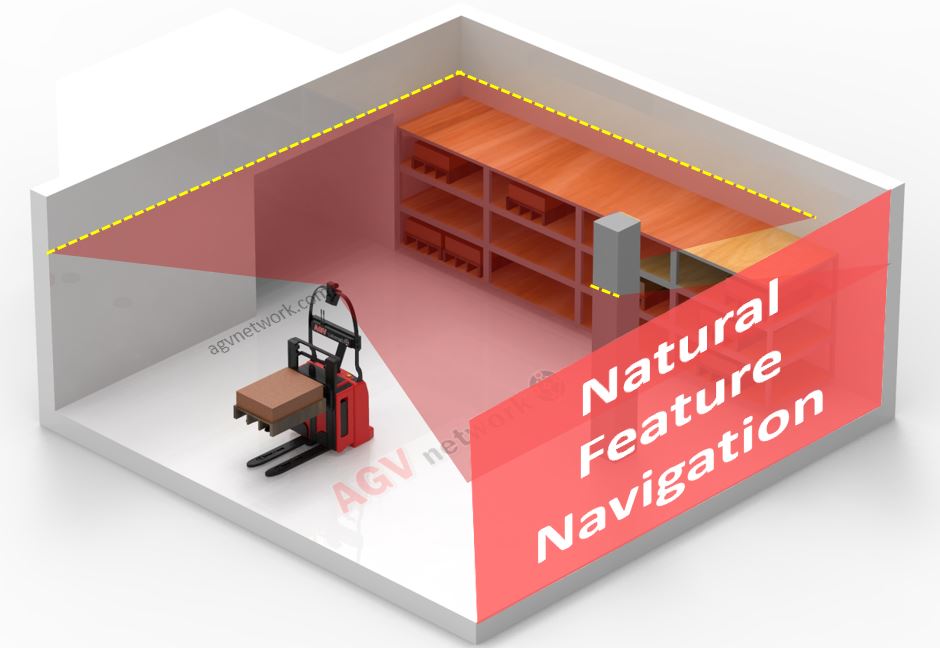

Natural Navigation

The AGV SLAM Navigation is becoming the KING navigation method in Hospital Environments.

Free or Natural navigation Automated Guided Vehicles navigate by identifying and mapping the surrounding area. Instead of following magnetic spots on the floor (or perform reflector triangulation) they can, for example, identify a defined wall and navigate at a given distance from it.

This navigation technology is completely structure “free”. Moreover, Natural Navigation allows to use data from cameras, built-in sensors and laser scanners to identify the environment and choose the most efficient route to the target.

In case an obstacle occurs in front of the AGV (in this case, also called AMR Autonomous Mobile Robots) it will safely manoeuvre around it, using the best alternative route. This optimizes productivity by ensuring that material flow stays on schedule.

Natural Navigation is still a “young” technology, suitable for not chaotic working environments with well-defined and stable contours.

Well, Hospitals are a good field for Natural Navigation implementation thanks to fixed walls, columns and other references along the way.

Automated AGV Hospital Safety System

A Hospitals is an environment completely different from a Industrial one. In Industrial applications you can train human operators about mobile robots behaviour and working rules for safety environment.

In Healthcare Structures, AGVs are more often moving in the same environment as people. You could train hospital staff to deal with AGVs but you cannot do it for patients, visitors, children and other external parties who could behave differently or unexpectedly.

For this reason, it is mandatory that AGVs are safety-certified with needed sensors and devices to minimize any kind of risk.

Suppliers must perform their risk analysis for every single project. The safety system must be configured individually for each vehicle type and each clinical working environment.

All the aspects related to AGV Safety are described in this post: What are the key rules for safer operation of AGVs?

Hospital AGV Management System

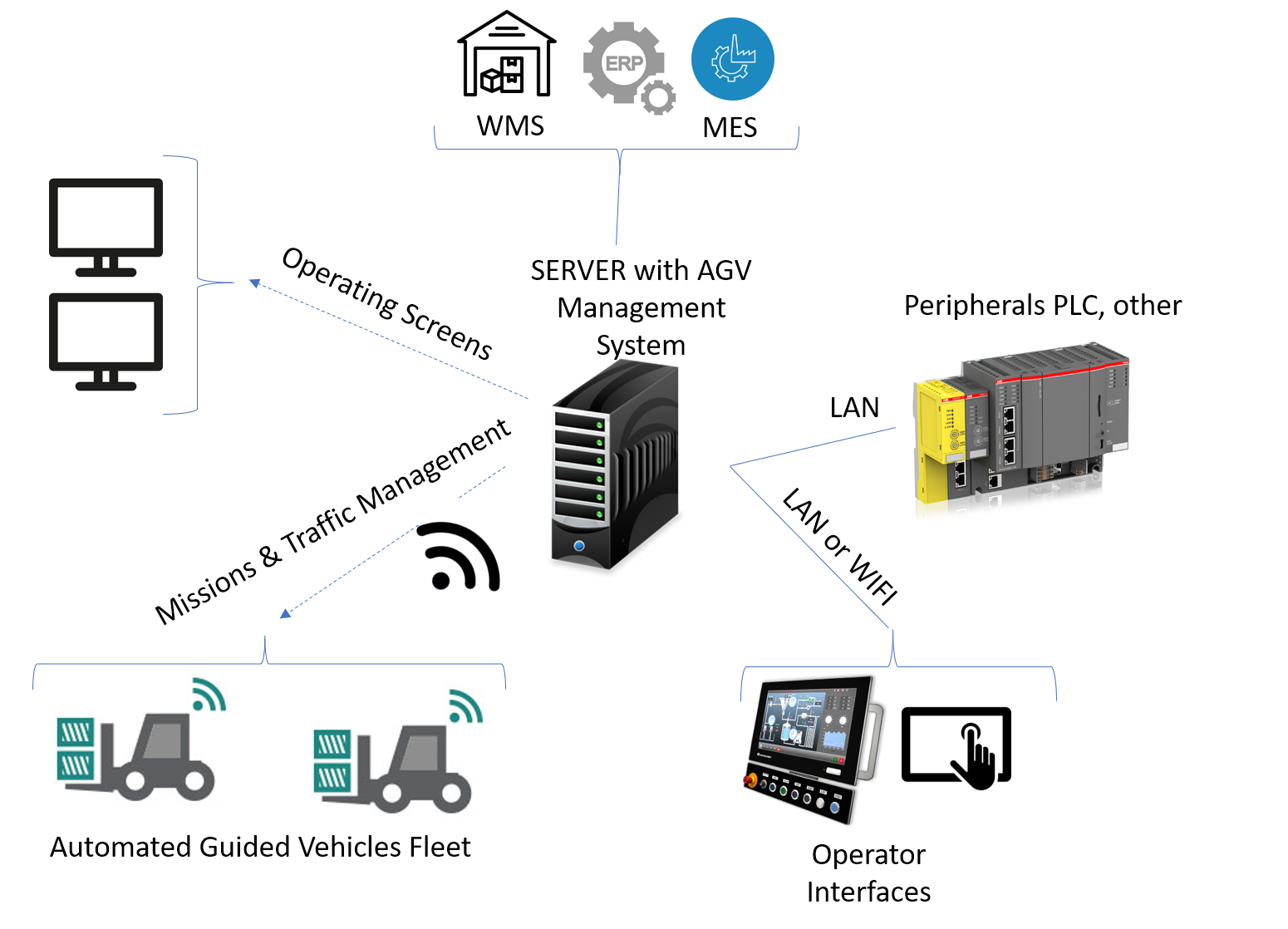

The AGV Management Software is the “brain” of the system.

Controlled centrally, the software allows the AGV system in a hospital to redirect and distribute the burden of incoming orders on-the-fly – achieving a coordinated interplay of fleet movement that maximises efficiency while providing instant reporting back through the system to trace performance, stock levels and interface with building management systems.

It assigns missions, which is the term used to describe the journey from one point to another. For example, a mission could be transporting a meal trolley to the lift lobby located near an inpatient unit.

The AGV drives underneath a trolley, and rises up lifting platform, lifting the trolley wheels off the ground during the journey.

The AGV Mission could indicate from “where” to “where” the AGV must go or could just indicate a reference such food kind, or defined bin… the AGV Warehouse Management System (WMS) would know where it is located a given material.

Once the AGV reaches its destination, it sends a notification indicating that the trolley has been delivered and is ready for collection.

The Management System can allocate a new mission for the AGV. If no mission is available, the Mobile Robot could return to “home” or go to the charging station.

Missions can be assigned directly by a superior Hospital ERP or by local, friendly panels and interface devices to allow staff to give instructions for a given task.

AGV Management System and the AGV itself should communicate with external world :

Elevators

Carts washing machines

Automatic doors

Facility Management System

Paging and Fire alarm system

Traceability: Hospital 4.0

Standard and special containers or carts are widely used together with healthcare AGVs.

AGVs are always connected with the AGV Management System so we always know where they are and what they are doing.

This feature drives further traceability of the load that can be traced in real time with infinite possibilities of integration with Hospital Management Software.

Containers differ in their usage and, depending on their features, are often permitted only in certain areas. AGV Traceability together with container (and its load) traceability allows for perfect understanding of “dynamic carts or containers warehouse,” being possible to know if they are in use, clean, dirty, etc.

Container and cart traceability can be achieved by several technologies such as bar code reading, RFID, etc.

On the other hand, AGVs must be able to catch this info to transfer it to the AGV Management System, so they must have devices able to read this info.

RFID systems are preferred for labelling containers which must be cleaned and disinfected regularly or for which the information, for example, state of cleanliness, needs to be updated.

Having up-to-date status matches with the 4.0 spirit lets hospital logistics provide a real and congruent representation of the actual flow of transport and goods.

The main benefits of the enhanced traceability are:

- Minimizing the occurrence of adverse events, as developed RFID systems facilitate the accurate identification of the cart and the correct destination and management.

- Ensuring that staff will administer the correct medication, meals, and general services, in the proper administrative conditions.

- Various health professionals will be able to check the location of materials and medications in real time, detecting potential bottlenecks and thereby significantly improving the efficiency of the hospital.

AGV and AMR MANUFACTURERS FOR HOSPITALS AND HEALTHCARE CENTERS

External References:

http://www.roboticautomation.com.au/agvs/hospital-agvs

https://www.ncbi.nlm.nih.gov/pubmed/28562681

https://www.tractmanager.com/blog/mobile-robots-healthcare-hospital-agvs/