8 Recommendations to Choose the Right Mobile Robot Supplier

I'm not going to say that when you select a mobile robot supplier you are going to marry them for the rest of your life. 👰🏽🤵🏽

I'm not going to say that when you select a mobile robot supplier you are going to marry them for the rest of your life. 👰🏽🤵🏽

But the mobile robot supplier selection is a very tricky decision because it could impact your current and future business.

Mobile robots are trendy, we all want to deploy mobile robotic systems:

|

The Global AGV market was valued $4,017.7 Million in 2021, and is projected to reach $8,661.1 Million by 2030 |

How to choose the right mobile robot supplier?

It doesn't matter if you are the end-user, or if you are an integrator or distributor of mobile robotics solutions. Make sure that you are choosing the right partner, or you will see your automation project fail sooner or later.

My name is Alfredo Pastor, I have bought mobile robots from many different suppliers... and some of them did not work as expected. 🤷🏽♂️

My name is Alfredo Pastor, I have bought mobile robots from many different suppliers... and some of them did not work as expected. 🤷🏽♂️

In the following lines, I indicate the main points that I always check when I evaluate a new mobile robot supplier.

These points or concerns are based on my own experience and mistakes.

Does your supplier have a wide product range?

I would choose a supplier able to supply different types of agvs (or mobile robots) with different specifications and technologies.

One of the most important things when it comes to choosing an AMR or Automated Guided Vehicle manufacturer is its mobile product range.

Initially, when you start to buy robots, you will probably need only one single model for your first application.

But, if you really care about automating different logistics flows, you should think about the future.

You will likely need to buy/install different types of mobile robots with different specifications.

Who knows? Higher payload, safer, some forklifts here, some tow tractors there, etc.

It would be great if your supplier was able to supply you with as many different solutions as possible.

Once you have decided who your supplier will be, you need to understand and manage its mobile robot technology: fleet management, navigation system, maintenance, spare parts, etc.

It might happen that you will not have the internal dedicated resources to afford different technologies contemporaneously.

The more types of AGVs and different technologies your supplier can deliver, the easier it will be for your technicians to manage them.

So, you can focus on your main operations: production, warehousing or even selling robotics systems if you are an integrator.

The supplier should be able to provide different types of agv technology too.

For example, if we talk about agv navigation technology, it would be better if your supplier was able to supply different types of navigation like magnetic navigation, autonomous amr navigation, laser guided vehicles, etc.

Each of these technologies has its own advantages and disadvantages and you want to be sure that when you face a project, you can offer the best available solution and not be bonded a defined technology.

Of course, there will be competitors offering a cheaper or a more sophisticated technology than yours.

|

Choose the supplier with the widest robot and technology range |

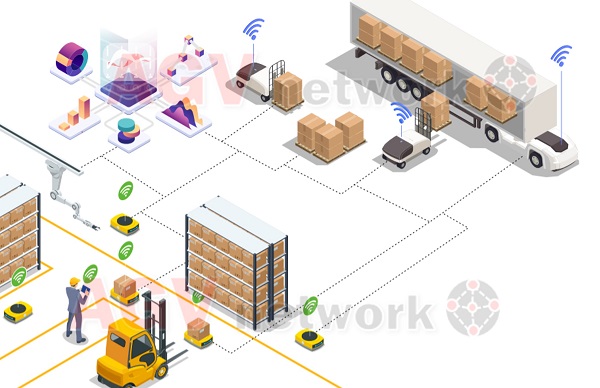

Is the mobile robot system interoperable?

Interoperability means that the mobile robot system can be integrated with other robotic systems from other vendors.

It means that the communication protocol has some defined specifications that allows such an integration (for example like the VDA 5050)

If you wish to know further about interoperability, do not miss this article: Why is Interoperability crucial for mobile robotic systems?

Imagine that you have installed a fleet of agv tuggers. After some months, you decide to install an autonomous floor scrubber robot to keep your premises clean. Even more, you would also like to deploy Security Robots.

What happens when your tuggers cross the scrubber? Who has priority? Can you monitor both systems from one single control software?

So, we come back to the previous point. The more robots your supplier can offer the better it is because they will probably use the same communication protocol or management system.

In any case, you will not find any supplier able to supply everything or, at the very least, everything at a competitive price.

Make sure that your supplier system is open to communicate with other systems.

At this stage, a good point could be if your supplier complies with VDA5050 protocol or a MassRobotics one.

|

Choose the supplier's system able to be integrated with other robotic systems |

Does your supplier offer “safe” mobile robot systems?

Let me tell you something. There is not any mandatory regulation or standard about safety for AGVs or AMRs.

Incredible.. isn't?

Nevertheless, there are some documents that even if not mandatory, represent reliable “guidelines” that all the manufacturers should follow while manufacturing or installing mobile robots safely.

The AGV Safety Standard in the US is ANSI/ITSDF B56.5-2019 and in EU EN ISO 3691-4:2023. If we talk about Mobile Industrial Robots (AMRs), the latest standard us the ANSI/RIA R15.08-1 and part 2

If you wish to know more about these documents, I suggest reading these articles.

|

AGV Network Related Articles: AGV Safety : Sensors, Standards, Rules |

The point here is, even if it is not mandatory, I would ask my supplier to comply with them and, if possible, that this compliance is certified by some type of third-party organization.

✅ Firstly, compliance with these documents means safer vehicles and systems.

✅ Secondly, compliance reflects supplier seriousness.

✅Thirdly, who knows if these standards will become mandatory sooner or later?

If you wish to know more about the standards and general safety info, you can download agvnetwork's whitepaper.

| Click here to download the whitepaper |

There is another important topic. Ok, now you have a safe vehicle but, has your supplier installed it ensuring safety?

For example, are safety scanner areas appropriate to vehicle speed and load weight (inertia)? Have you identified all the hazard zones? What measures has your supplier implemented to minimize the risk?

This is to say, make sure that your supplier has a wide experience in risk assessment when it comes to installing mobile robot systems.

Every new AGV/AMR must be designed with a relevant Risk Assessment analysis, same as their installation. Discover SICK guys explaining how to perform a risk assessment for AMRs/AGVs, what are the latest SICK solutions, etc. Absolutely... a MUST watch!

| Click here to watch the webinar |

I can't believe that I'm highlighting this... 😬

|

Choose the supplier's offering safe robotic systems |

Global and local presence

How does your supplier support your future activities in case of need?

Is your supplier far away? What time zone? What is its response time?

If you’re focus is in one single country, you should make sure that your supplier is close to you and who cares if your supplier is a worldwide player.

You need fast and prompt response for whatever reason and, if possible, it is much better if your supplier speaks your native language.

On the other hand, if your company has global operations with factories or warehouses all around the world, you should really care about your suppliers’ capability to support you in these areas.

There are few suppliers able to support your operations globally with their own resources.

What mobile robot suppliers used to do instead is find local partners or integrators that are locally present to support your needs fast and efficiently in your area.

So, in case you are a global player, and you are willing to have one big global supplier, make sure that your supplier has a well-established distribution network in the countries where you would like to install these mobile robots.

Pay attention, because as far as I have seen, many suppliers declare that they have a wide integrator network but when you go to check them, you realize that not all of them are technically ready to support complex AGV or AMR projects.

I suggest checking one by one who these integrators are and what they are really doing in your country.

The last thing that you would like to suffer is to have your AGV system down, but your local service center is not able to support you due to a time zone difference, so you must wait for the manufacturer to open its technical support.

Anyway, even if it would be great to have one supplier able to support you worldwide, it is very complex to find the right one.

First, as explained in the point above, not all suppliers have the same vehicles.

Secondly, even if you’re able to find a supplier that can support you in different areas, there is no guarantee that this supplier will be the most competitive.

I would try to find suppliers in different macro areas: Europe, America, etc. Of course, these areas can also be segmented. If you find a supplier able to support you in more than one of them, good for you.

|

Choose the supplier that better suits for your local operations |

Is your mobile robot supplier financially stable?

Well, this point could be understood as a very generic one for whoever the supplier is.

The mobile robot industry is quite young so there are many start-ups with very cool products but that are not mature enough yet.

Clearly, we do not want to see our supplier closing the door for bankruptcy, but let’s not be so dramatic.

The mobile robot technology is evolving very fast, and if your mobile robot supplier is not financially stable and does not have the possibility to grow, it could probably have problems in developing new solutions to stay ahead of the market.

You could start with an incredible technology that in a few years has become old fashioned because your supplier has not developed anything new.

|

Choose the supplier that ensures long term innovation capabilities |

Is your mobile robot supplier competitive?

Ok, this is applicable for whatever you wish to buy.

When speaking about mobile robotics, there are two competitiveness levels to check.

✅ Is your supplier competitive versus actual manned solutions?

The manned solution is the main benchmark.

You can have a great mobile robot solution with tons of innovation but if it is more expensive than actual manned solutions, you will probably not sell the system.

Yes, of course, there are other advantages of automated guided vehicles like safety, less mistakes, less indirect costs, etc, but if the automated system payback is not positive, you have a 90% probability of saying goodbye to the automated solution.

✅ Is your supplier competitive versus other mobile robot solutions?

Mobile robot manufacturers are springing up like mushrooms ????.

Let’s say that you have defined the solution that better suits your requirements and you’re able to compare apples to apples.

You will probably choose the most convenient one for your specific application. Congrats!

Once you have decided on your mobile supplier, do not think that this supplier will never be in your life anymore.

At a given point, maybe you will have some issue to be solved or maybe you would like to modify or expand the project.

Pay attention to the service cost.

Almost no one checks this point. The AGV system maintenance cost could be very, very relevant.

I would pay more to a supplier if I’m sure that in the future this supplier will not kill me with service costs.

I mean, ask your supplier for a detailed spare parts price and hourly rate in case you need his services.

I’ve seen suppliers asking more than $500 only for answering a call. I’m saying answering, not solving a problem ????.

I’m not saying that is not fair or wrong, I’m saying that it’s better if you’re aware of these costs from the beginning.

|

Choose the supplier that ensures robots and service competitiveness |

Is the mobile robot system easy to modify?

Let me tell you something, all the mobile robot suppliers will tell you that their system is easy to modify and scale once it is installed in your premises.

Honestly: it is not true.

Or at least, it's not as easy as the supplier will tell you. Whatever the modification, you will need to have some advanced technical knowledge.

There are systems that are easier than others, and that allows more freedom when it comes to modify something. But you will almost never have the full control and unlimited modification possibilities.

If you want to integrate the mobile robot system with your own management (let’s say WMS or ERP), you will absolutely need the supplier’s support whenever you’ll wish to modify something.

If we talk about navigation, the latest Autonomous Mobile Robots offer really flexible tools to allow you to modify tracks effortless. Yes, you can change a route, but the actions to be done by the robot could be limited.

I want to highlight something (already anticipated). Let's imagine that you are able to modify the speed and track of your mobile robot by your own. Remember that whenever you change a parameter, you should perform a risk assessment for that modification.

It means that you have to be sure that you have not created a new risk and/or that you have taken all the relevant activities to minimize it.

Imagine that, for example, your new track passes too close to a wall where there is no escape route for operators. Have you identified this risk? Is your supplier or yourself prepared for such an operation?

|

Choose the supplier that offers an user-friendly management and navigation system |

Find a supplier with standard components

If I had to buy at mobile robot I would make an in-depth analysis of its components and technology.

Make sure that your mobile robot supplier uses components that are easy to find in your local market.

I'm talking about PLCs, photocells, scanners, drivers, wheel drives, encoders, etc, everything.

There are many fancy components out there but, in some occasions, these components are supplied from overseas or by small companies that do not have local distributors in your local market.

I guess you do not want to have your mobile robot stopped several weeks because you are waiting the delivery of a $200 component.

This is particularly important when we talk about self-developed and produced components. Only your supplier will be able to provide you that component, what is a problem for your future independency.

|

Choose the supplier that utilizes standard components |

I hope that you have enjoyed the article. If so, please share it!!

If you think that I'm missing some topic... feel free to write here:

|

Related articles

Automated Guided Vehicle Manufacturers List |

Written by Alfredo Pastor Tella (agvnetwork editor).

Written by Alfredo Pastor Tella (agvnetwork editor).

Follow me on LinkedIn... let's create a mobile robot community to discuss and learn about these outstanding systems.