AGV Battery - What is the best type for your project? Battery Cost?

What is the best battery technology for an AGV? GEL, Lithium, lead-acid?

In this article, I explain the different types of batteries that are commonly used in the AGV industry.

What types of batteries do AGV and AMR use?

- Sealed GEL Bateries

- AGM Pure-Lead

- Lithium Batteries

- Flooded Lead Acid

What is the best type of AGV Battery?

The optimal type of AGV battery is determined by the agv battery charging systems chosen. In reality, battery type and charging technology are closely related.

The charging technology (opportunity charging or battery swap) is the key factor to define the best technical and economical solution.

I suggest to read this article: AGV Battery Charging Systems, that explains the different methods used for battery recharging in the mobile robot industry.

There are numerous factors involved in battery selection, including cost, recharge time, robot type, etc.

The table below provides an introduction to these subjects, that I'll explain further in the following chapters.

Specification GEL PURE-LEAD LITHIUM FLA Suitable for Online Charging

Depth of Discharge (DOD)

Suitable for Fast Charging

Battery Life

Gas emission

Need of maintenance

Need Vehicle modification

Battery Price

|

Pure-lead batteries for Automated Guided Vehicles Lithium batteries for Automated Guided Vehicles Cost comparison between Lithium and Lead batteries for an AGV system |

By the way... before going ahead.. do not miss agvnetwork's whitepaper with detailed information mobile robots batteries and charging systems.

| Click here to download the whitepaper |

AGM and GEL batteries for AGVs

AGM and GEL batteries are widely used in the AGV industry. They are Sealed Lead-Acid (SLA) or valve-regulated lead-acid battery (VRLA battery). Check this link with more detailed technical info.

Regardless the specific differences between AGM and GEL batteries (they are more or less the same), both types present the following attributes:

✅ They are sealed and non-spillable batteries.

✅ They do not need maintenance, so they are maintenance-free.

✅They are "Deep cycle" batteries. It means that the battery can be discharged down up to 80% (so when it only remains 20% capacity in the battery).

✅They have low self-discharge rate.

✅ They present low gas emissions or not emissions at all. They can be used aand recharged in limited ventilation areas.

✅ They are robust and can be transported safely without any special handling care.

These characteristics above, make GEL batteries a great option for mobile robot AGV purposes... but not always, we'll see later.

How long does a GEL battery last before recharging is needed?

It depends on the battery dimension and the type of agv robot. In order to give you an idea you can consider as follows:

- In big AGVs such AGV Forklifts, GEL batteries last around one shift, so the same as manual forklifts.

- In small Tugger AGV or automated guided carts , GEL batteries can last up to 12-16 hours.

These numbers are reachable and are a good trade between battery working time and battery life.

In general, it is suitable to recharge GEL batteries when they reach 40%-50% of DOD (depth of discharge).

Of course, this info depends on the specific mobile robot system and vehicle of type.

Typically, the battery consumption is lower in AGVs than in human manned vehicles because AGVs drive smooth and do not brake and accelerate continuosly.

How long does it take to recharge a GEL battery for AGV?

Typical recharging time is around 5 hours.

What is GEL battery cycle life (life time)?

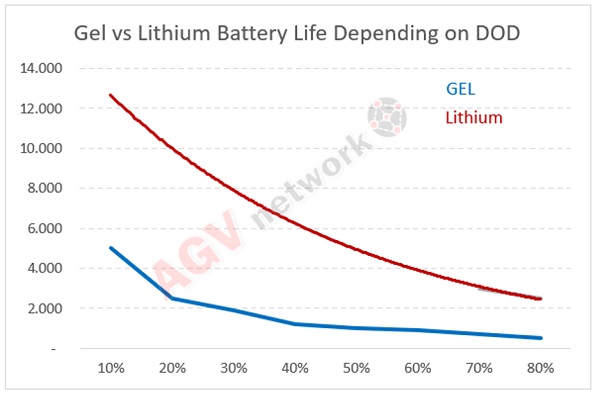

The graph below shows the battery life in Number Of Recharging Cycles depending on the Depth of Discharge.

As you can see, the battery life is near 1200 cycles for a 40% DOD. It means that you can recharge 1200 times your GEL from 60% to 100%.

For example, if your company works 2 shifts, 5 days a week and you must recharge the battery around 10 times/week, your GEL battery will last around 3 years.

What AGV systems are suitable for AGM or GEL batteries?

- AGV systems working two or three shifts. In this case, you should need a second battery to perform battery swap.

- AGV systems working one shift. In this case, it could be enough to have only one battery that can be recharged during non-working shifts. Note: Check that AGV System energy balance allows this option.

What about AGM/GEL batteries for opportunity charging?

GEL batteries are not the best option for opportunity charging.

If you need to perform short and fast partial charging many times you will kill the battery soon.

These batteries are designed to be fully recharged once they reach a depth of discharge of around 40% or 60%.

AGM/GEL batteries allow recharging with current around 25-30% of its capacity.

If you have a battery of 150 Amp/h, then, recharge must be done at maximum 35-40 Amp/h, otherwise battery could be damaged.

The only way to keep a good battery life and perform opportunity charging, is to stop the AGV in the charging station for a long time. If you perform short fast charging many times you will kill the battery soon.

|

Note ????: Avoid AGM/GEL batteries for opportunity charging systems unless opportunity charging means several hours for recharging. |

Pure-lead AGM batteries for Automated Guided Vehicles

The pure-lead batteries are a good option to consider if your AGV project requires opportunity charging.

What are pure-lead batteries?

The pure-lead batteries are an specific type of advanced AGM batteries having pure-lead thin plates rather than standard lead-calcium plates.

For detailed technical info, you can check this video.

What AGV systems are suitable for Pure-lead batteries?

For what regards pure-lead batteries application in AGV projects, they are an optimal solution for systems requiring opportunity charging.

I summarize here below the main advantages and disadvantages of pure-lead batteries.

Advantages of pure-lead batteries

✅ They have excellence battery life, near 1200 cycles with 60% depth of discharge.

✅ They support short fast recharging without compromising battery life.

✅ They support high current recharging up to 50% of battery capacity compared with 30% admitted by GEL batteries (0,5C instead of 0,3C).

If you have a 150A/h capacity pure-lead battery, you can recharge it at 75A/h. If it were GEL, you could only refuel at approximately 30 A/h. So pure lead charging is nearly three times faster.

✅ They are sealed batteries with very low gas emissions.

✅ They are maintenance free.

Disdvantages of pure-lead batteries

❌ As indicated, pure-lead batteries have low gas emissions while recharging (they are not fully gas free). You should check in your local regulations what is the air volume needed in the recharging station to guarantee gas dispersion (in Europe is CEI EN 62485-3).

Based on my experience, 95% of standard factories and warehouses accomplish with local regulations, so there is no problem for recharging them indoor without forced ventilation device. But, it is better if you check it your local regulations.

❌ Pure-lead batteries cost is higher than standard AGM/GEL batteries even if they are less expensive than Lithium batteries.

Lithium batteries for Automated Guided Vehicles

Lithium batteries are more and more used in the AGV industry. There are several reasons why Lithium batteries are acquiring market share.

In some cases, such inductive agv wireless charging, Lithium batteries are the best option. Contactless charging technology reaches near 95% efficiency and needs batteries able to receive a big amount of energy in fast charging cycles for this reason are a great option as wireless charging for amr.

What are the Advantages of Lithium batteries for the AGV industry compared with FLA or GEL and AGM batteries?

-

Longer cycle life time

For a given depth of discharge (DOD), Lithium batteries grant more recharging cycles so more life.

So, if you always discharge the AGV battery to 50% of its capacity, SLA (GEL/AGM) had around 1500-1800 recharging cycles lifetime. With the same 50% DOD, the Lithium battery lasts for 5000 cycles.

- Deepest Depth of Discharge (DOD)

As explained before, in order to have a good cycle life for an AGM or GEL battery you should keep DOD close to 40%-50%. It means that if you have a 100 Ah battery you can use around 40 or 50 Ah before you need to recharge.

Lithium batteries can handle DOD of 80% maintaining excellent battery life (still close to 2500 cycles).

With the same 100 Ah battery, you can use 80 Ah before you need to recharge. It means more time availability for your AGV to perform missions rather than “losing” time for recharging.

-

Lithium batteries Efficiency is higher

Lithium batteries are more efficient. Lithium batteries efficiency is near 95% while in Lead batteries such AGM or GEL, it is close to 80-85%.

Roughly, it means that if you charge 1 kwatt, a lithium battery losses around 50 watts (you really get 950 watts).

Lead battery instead, loses 15-20%, it means that you will need more time to fully charge your AGM/GEL battery.

-

Lithium batteries charge rate is faster

While charging, you can pump more Amperes/hour without compromising battery life, so again, you can charge battery much faster.

In AGM/GEL batteries you needed around 4-5 hours to charge from 60% to 100%. With lithium you only need close to 1,5 hours.

This feature is essential for AGV systems with opportunity charging.

With Lithium batteries you should only need 10% of AGV cycle time, it means that your AGVs are available more time for performing missions and transporting materials.

-

Higher Energy Density

More energy available in a given volume. In other words, the same power and less weight or the same weight and more power.

We can consider that the energy density in Lithium batteries is three times higher than in the lead batteries.

Graph from www.medium.com

What are the disadvantages of Lithium batteries for AGVs?

Until now, we have only seen “good” things. So, why do lithium batteries still have a reduced AGV market share?

-

Lithium batteries require protection

Lithium batteries are instable. They need protection against overcharging. The energy current must be kept into defined safety levels.

Lithium batteries require complex electronics to keep all these parameters under control and maintain safe operating conditions.

Another negative aspect related to the point above is that Lithium batteries has restrictions for transportation, especially by air transportation.

- Lithium battery technology is not mature yet

Lithium technology is still considered to be “under development” so technology keeps on changing and does not remain constant.

Many AGV producers do not invest in Lithium because they fear that the investment payback might never arrive because of some technology variation.

-

Lithium batteries cost is still more expensive

If we consider the points above, everything suggest that Lithium batteries are cheaper than other kinds of batteries. They last more time, the AGVs can be used better, they can store more energy, etc.

The problem is that the initial investment is still higher than compared with other types of batteries. We all know that available money for investment is always limited.

Typically, a lithium battery costs 3 to 4 times more than an AGM/GEL battery.

Flooded Lead-Acid (FLA)

FLA batteries have many disadvantages even though they can be used in specific AGV system conditions.

The main disadvantages of FLA batteries for AGV systems

❌ They emit gases while charging, so they need special ventilation devices and dedicated areas

❌They need maintenance

Basically, FLA batteries are not used in small AGVs such platforms, under carts or small AGV tuggers. FLAs are only used in big AGVs (mainly LGVs) comparable with traditional forklifts or big tow tractors.

Main advantage of FLA batteries for AGVs

✅ They are the cheapest in the market

When are FLA batteries suitable for AGV system?

- They are suitable if they can be recharged outdoor or in ventilated areas for charging

Cost comparison between Lithium and Lead batteries for an AGV system

MOBILE ROBOTS --- GEL vs Lithium, the never-ending fight

This picture above is taken from the Mobile Robots Types of batteries and Charging Systems. Download it now for more nice info.

Imagine that you have an AGV system with 3 AGVs. This system has an overall AGV global saturation of 90%, so AGVs would have 10% of their time to perform online charging.

If you had pure-lead batteries, you could not perform on-line charging because you would need around 30% free spare time. You would need the fourth AGV to have a global system saturation of around 70%.

With Lithium batteries you could perform online recharging with only 3 AGVs.

???? I guess you have understood. Do Lithium battery extra cost compensate the additional AGV?

In these borderline cases where your AGV System saturation is between 70% and 90% it could be convenient to have Lithium batteries.

There is not a rule to define the point where the Lithium batteries become more convenient. It depends on the AGV system itself.

Check here below some points to taken into consideration.

- Number of shifts. Of course, if you consider that Lithium batteries are more expensive, more hours the AGVs work and more convenient it becomes the lithium technology.

- AGV system recharging strategy. Considering Lithium technical features, it is suitable for AGV systems with opportunity charging strategy.

Every AGV system must be analysed to define the best battery technology

Check this article if you want to have more detailed technical information about general battery technology.

|

Related articles What is an Automated Guided Vehicle? AGV Wireless Charging? Manufacturers? Cost? Advantages? AGV cost estimation. How much does an automated guided vehicle cost? |

Written by Alfredo Pastor Tella (agvnetwork editor).

Written by Alfredo Pastor Tella (agvnetwork editor).

Follow me on LinkedIn... let's create a mobile robot community to discuss and learn about these outstanding systems.