6 Types of Robot Forklift to boost your material handling

The main types of robotic forklifts are:

- Pallet mover (also called pallet jack) for floor to floor operations

- Pallet Stacker

- Counterbalanced Fork truck

- Straddle Vehicle

- VNA- Very Narrow Aisles AGVs

- Reach Truck

As you can see, the same type of manned vehicles can be turned into automated machines.

Before delving into the many varieties of robotic forklifts, I recommend that you download "The Robotic Forklift Guide", which covers many other subjects such as cost, safety, navigation, and so on.

Donot miss it: It's free... ????

| Download The AGV Forklift Guide |

💡 Of course, each type of vehicle will have a defined application and will have specific advantages and disadvantages.

It is crucial to know them... and to know what are their limitations, in order to choose the right kind of robotic forklift for your specific application.

For example, depending on the navigation method, we could have agv forklifts or autonomous forklifts.

My name is Alfredo Pastor, in this article I explain what are the main types of robot forklifts with their typical specificications.

My name is Alfredo Pastor, in this article I explain what are the main types of robot forklifts with their typical specificications.

For instance... have a look at some of the robot forklifts that can be found in the agvnetwork showroom. 👀

| ROBOT FORKLIFT TYPE | PICTURE | What's the best? |

|---|---|---|

| AUTOMATED PALLET JACK |

| Fast movement for floor to floor operations |

| COUNTERBALANCE |

| High payload capacity |

| OUTRIGGER |

| High payload capacity with reduced footprint |

| AUTOMATED REACH TRUCK |

| Great for combination for high racking and possibility to run out from warehouse aisles |

| VERY NARROW AISLE VNA |

| The king of racking warehouses. High height capacity Increase warehouse capacity |

🙋🏼♂️ If you're finding this article helpful (hopefully yes...), please share it! 👇

| FORKLIFT AGV TYPE | PALLET MOVER | COUNTERBALANCE | OUTRIGGER | REACH TRUCK | VNA |

|---|---|---|---|---|---|

| VEHICLE EXAMPLE | |||||

| Racking Warehouse MINIMUM AISLE WIDTH (Distance between pallets) | 3,6 m/140'/11,8ft | 4,5m/177'/14,7 ft | 3,7m/145'/12,1 ft | 3m/118'/9,84ft | 1,6m/ 63' / 5,3 ft |

| MAX SPEED FORWARD | 2 m/s - 386 ft/min | 2 m/s - 386 ft/min | 2 m/s - 386 ft/min | 2 m/s - 386 ft/min | 2 m/s - 386 ft/min |

| LOAD STORAGE HEIGHT | 1,5 m / 60' /4,9 ft | 9 m /354 '/ 29,5 ft | 4 m / 157'/ 13 ft | 9 m /354 '/ 29,5 ft | 11 m / 430' / 36 ft |

| MAX LOAD CAPACITY | 1.500 kg /3.300 lbs | 2.500 kg / 5.500 lbs | 1.500 kg /3.300 lbs | 1.500 kg /3.300 lbs | 1.200 kg / 2.645 lbs |

| VEHICLE PRICE | $60.000 | $85.000- $120.000 | $85.000- $120.000 | $120.000- $150.000 | $150.000 - $200.00 |

Let's discover them one by one

What are the main types of Robotic Forklifts?

Automated Pallet Mover

A Pallet Mover AGV also known as Fork-over AGV or simply Automated Pallet Jack, is a type of robotic forklift conceived to transport palletized loads in manufacturing facilities.

The solution is inspired by the conventional pallet jack. This application allows limited vertical movement of the load, reaching pallets on racks or shelves at low height or in floor-to-floor operations.

| ||

|---|---|---|

| PALLET JACK AGV | ||

| Pros | Cons | |

|

| |

The transport capacity of an automated pallet jack varies from few hundred kilograms to several tons.

The automated pallet movers are the “smallest” of the unmanned forklift category.

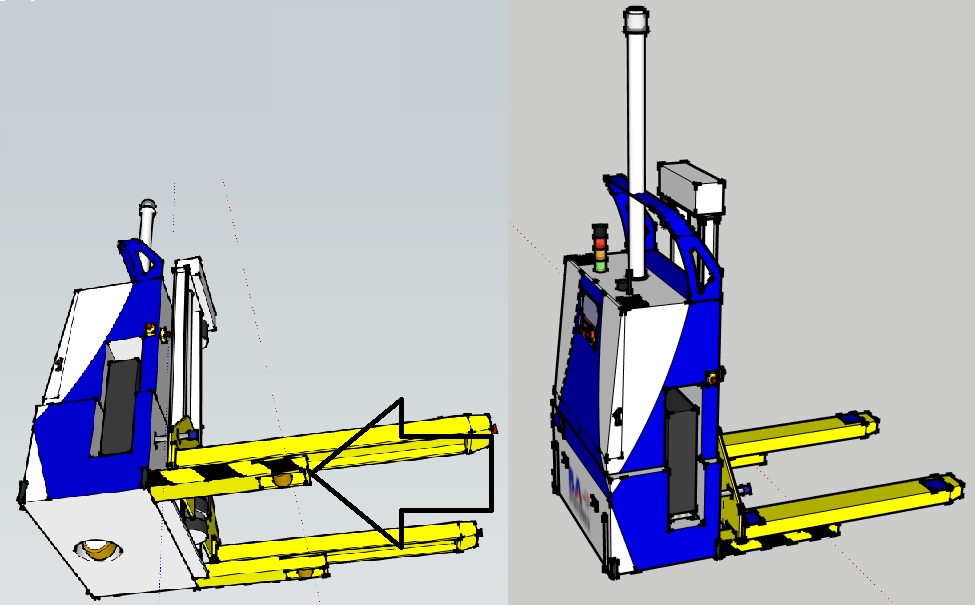

Automated Pallet Movers have stabilizers located beneath the forks. The stabilizers allow reduced AGV dimensions, weight, and a permit tight turning radius, ensuring great maneuverability.

Fork over AGV picture from https://3dwarehouse.sketchup.com/

Counterbalanced Robotic Forklift

A counterbalanced AGV lift truck is a forklift that counterbalances the weight of the load with a weight, usually cast iron or the battery, in the rear of the truck.

It is used whenever it is not possible to use fork-over AGVs and whenever is needed high payload and stacking height capacity.

Click here to discover more about Kollmorgen Solutions for AGVs and Mobile Robots

Counterbalanced AGVs are mostly used for shipping and receiving loads and they are an ideal automated lift trucks for moving pallets to and from storage.

These vehicles are bigger and need more space for turning radius, but they can handle heavy loads and can reach higher stacking heights.

COUNTERBALANCE - FORKLIFT TRUCK Pros Cons High stacking and payload capacity Large footprint

Straddle Forklift (outrigger AGV)

STRADDLE or OUTRIGGER - FORKLIFT TRUCK Pros Cons

Straddle Robotic Forklifts, commonly referred to as outrigger AGVs, feature two horizontal stabilizing legs extending beyond the load's width.

This unique design enables these robotic straddle stackers to require less maneuvering space compared to their counterbalanced counterparts.

Additionally, the support legs significantly enhance stability, both when lifting and during transit, ensuring a safer and more efficient operation.

VNA Very Narrow Aisle Automated Guided Vehicles

VNAs are the most efficient AGV to perform transportation tasks in big and high warehouses.

Click here to discover more about Kollmorgen Solutions for AGVs and Mobile Robots

These forklifts are the most costly of the forklift range but also the best at their job, which is moving pallets on high density racks.

🤔 Imagine what?

Very Narrow Aisle AGV work in “very narrow” aisles. Reducing aisles width it is possible to increase warehouse storage capacity.

| ||

|---|---|---|

| VNA AGV - VERY NARROW AISLE | ||

| Pros | Cons | |

|

| |

If you wish to learn further about this type of foklift, I wrote a whole article about the VNA Truck AGV . Don't miss it.

AGV Reach truck

AGV Reach trucks are robotic forklifts made for tight spaces in narrow-aisle warehouses.

They come with two outer legs that help balance the weight of the load. The mast of the truck can move the forks beyond the base of the vehicle, which makes it easier to move around.

Some of main advantages of the reach truck AGV is the performant lifting speed and limited footprint.

| ||

|---|---|---|

| REACH TRUCK AGV | ||

| Pros | Cons | |

|

| |

|

Related articles...to learn more about Robot Forklifts

How to calculate an AGV system Payback - Download our free Payback Calculator AMAZON Robots - What mobile robots does Amazon use? What can AGV Warehouse robots do? AGV Pick Up Pallet Methods Automated Reach Trucks - The king of the warehouse VNA AGV - List of Manufacturers and Characteristics of Very Narrow Aisle Robots Automated Pallet Jack Discovering the Self Driving Pallet Jack |

Written by Alfredo Pastor Tella (agvnetwork editor).

Written by Alfredo Pastor Tella (agvnetwork editor).

Follow me on LinkedIn... let's create a mobile robot community to discuss and learn about these outstanding systems.